P35.002: Conductor, Shield Wire, and Hardware Corrosion

Objective

The overhead transmission system comprises materials that are susceptible to atmospheric corrosion that degrades their mechanical strength and may result in mechanical failure of the overhead transmission line. To ensure safe and reliable power transmission, it is essential that we understand the impact of corrosion on the durability of line assets. Understanding the corrosion of an overhead transmission line requires an understanding of its surrounding environment and how the conductors, shield wires, and hardware components age because of those environmental factors.

The objective of this project is to gain an understanding of how overhead transmission conductor, shield wire, and their associated hardware corrode; understand the efficacy of corrosion inhibition methods; and determine the service life of these components in various corrosive environments. Asset managers can then use this knowledge to select components best suited to their specific environmental conditions, set timelines for inspection, and prescribe mitigation or remediation actions.

This project aims to provide:

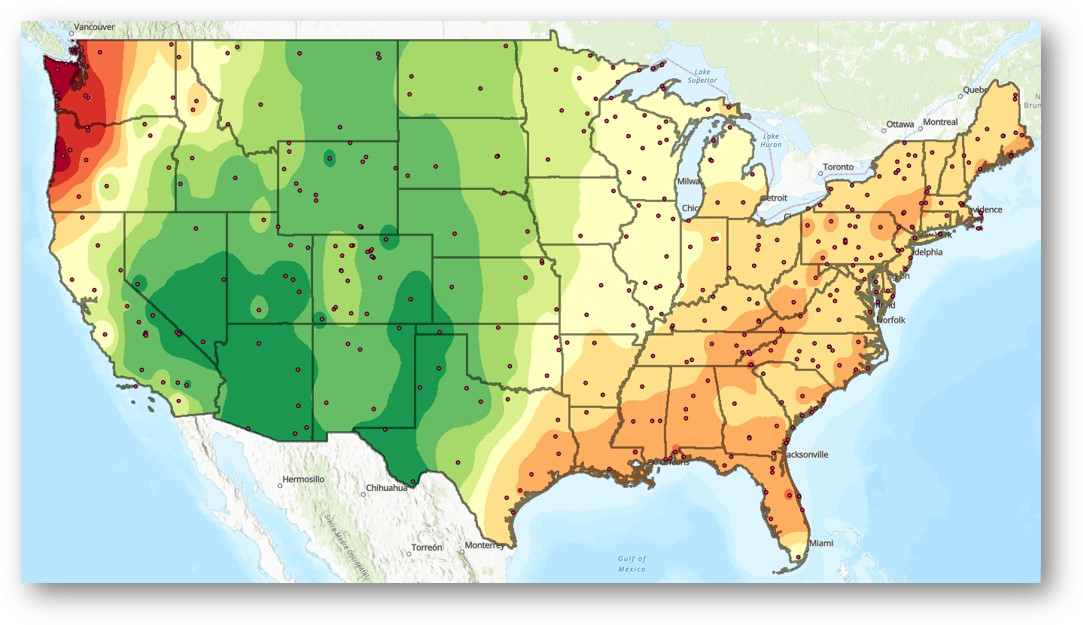

- A geographic information system (GIS) based corrosion map to identify locations of severe atmospheric corrosion

- A guideline for the selection of aluminum conductor steel reinforced (ACSR) and aluminum conductor steel supported (ACSS) conductors for corrosive areas

- Guidelines to understand all aluminum conductor (AAC), aluminum conductor alloy reinforced (ACAR) conductor, and all aluminum alloy conductor corrosion

- An end-of-life calculator for ACSR and ACSS conductors

- A review of uses and limitations of grease conductors

- A reference book for transmission asset corrosion

- Conductor corrosion condition assessment guidelines and best practices

Research Value

Research on corrosion of conductor, shield wire, and line hardware is intended to improve the safety, reliability, and efficiency of the overhead transmission system for member utilities and the public by:

- Improving the selection of materials based on the environmental conditions

- Providing effective corrosion mitigation strategies based on the materials and environmental conditions

- Providing anticipated degradation rates to assist in determining effective inspection and/or remediation prioritization

Planned 2025 Research

This project addresses the issues surrounding corrosion of conductors, shield wires, and hardware by providing members with the tools and knowledge to make the most informed and cost-effective management decisions regarding the asset’s maintenance, inspection, and selection. Improved corrosion management may be achieved by using new inspection techniques, better assessment practices, and mitigation methods. The following core tasks are underway:

All Aluminum Conductor (AAC), Aluminum Conductor Alloy Reinforced (ACAR) Conductor, and All Aluminum Alloy Conductor Corrosion: Aluminum strand degradation may occur because of intergranular corrosion and manifests itself as exfoliation, resulting in a brittle aluminum strand. Preliminary research has shown that a comparison of tensile strength and torsional strength may provide a reliable metric for determining the remaining service life of an all-aluminum conductor. The corrosion resistance of the different aluminum alloys used in overhead conductor is also intended to be studied in this task. The goal of this task is to understand and categorize the severity of the degradation in terms of this new metric, correlate that metric with service life, and use that information to select where all-aluminum conductor performance will be maximized.

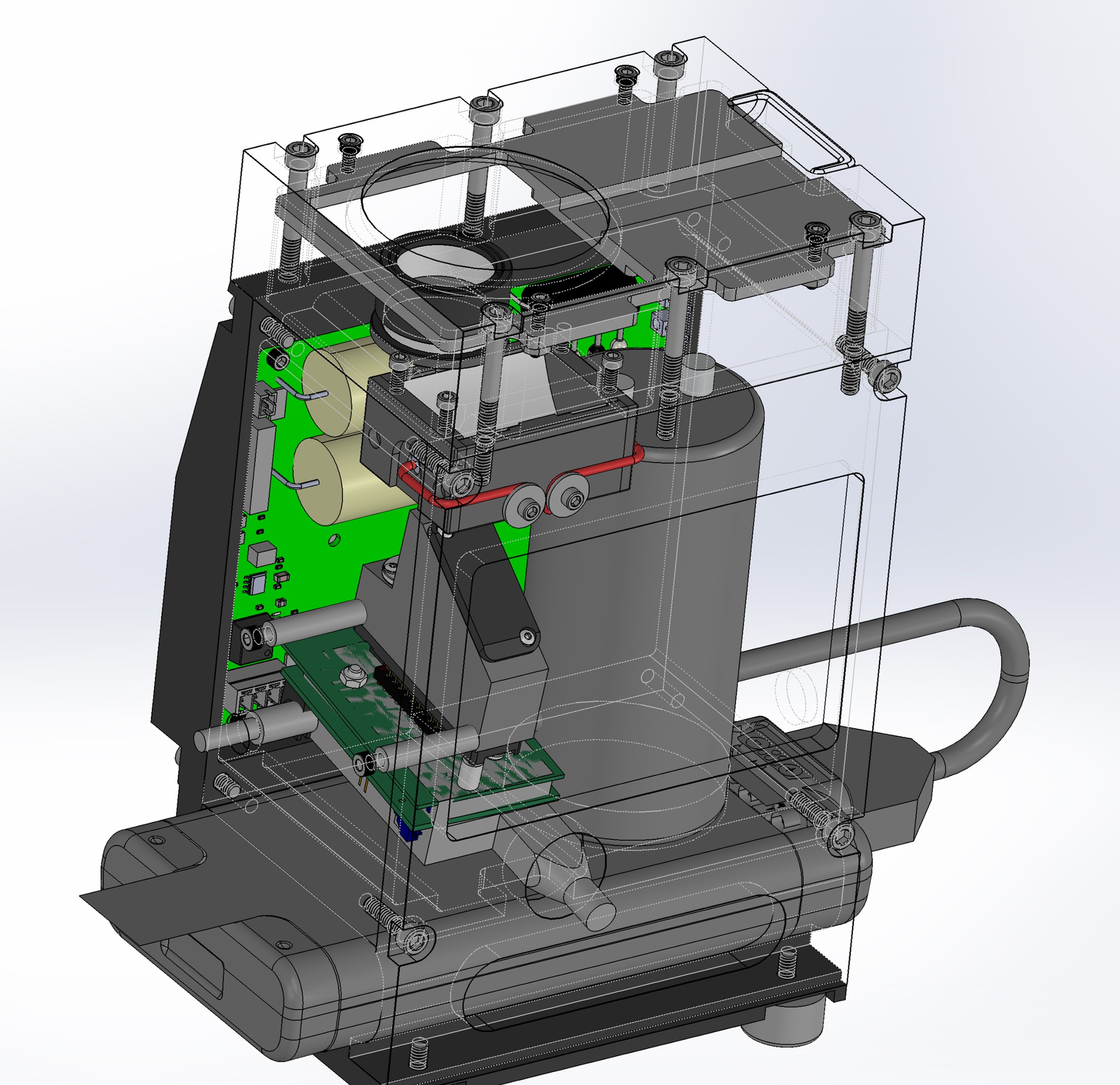

Conductor Inspection Tools: EPRI intends to continue the development of its own conductor inspection technology based on spectroscopy and a 2D profiler. The current version of the C-Corr is drone based to allow more flexibility in the inspection process. In parallel, EPRI intends to monitor for new and emerging conductor corrosion inspection technologies that can be of potential interest for its members.

Evaluation of New Conductor Grease: Greased conductors have been found in laboratory experiments to offer significantly more corrosion protection than non-greased conductors. Ongoing research is exploring the advantages and limitations of using greased conductors as well as new and emerging grease products. EPRI intends to continue to investigate a new grease that chemically bonds to the galvanizing and becomes a stable patina to resist corrosion. The benefit of this bond to the galvanizing is that the grease dropping point is eliminated and higher operating temperatures may be implemented without losing the corrosion protection.

Atmospheric Corrosivity Maps for Conductor Modeling: EPRI intends to continue its development of atmospheric corrosion maps to allow engineers to model the degradation rates of various metals and overhead components based on the surrounding environment or geographic locations. The vision of use is for utilities to identify locations where their conductors, shield wires, and hardware are at risk because of corrosion and allow optimizing of inspection program and reconductoring projects.

Condition Assessment of In-Service Conductors or Conductor Failure: EPRI intends to continue adding results from conductor health assessments into a report to help utilities understand how conductors degrade and the environments that caused the degradation. This task produces a living document covering the initiation mechanisms specific to each construction material and type of conductor. It provides guidance on selecting the appropriate test techniques to quantify each sensitivity and identify or eliminate that as a cause of failure. The realized value to the utility is that an understanding of what causes conductor degradation in the field may be considered in the design and installation.

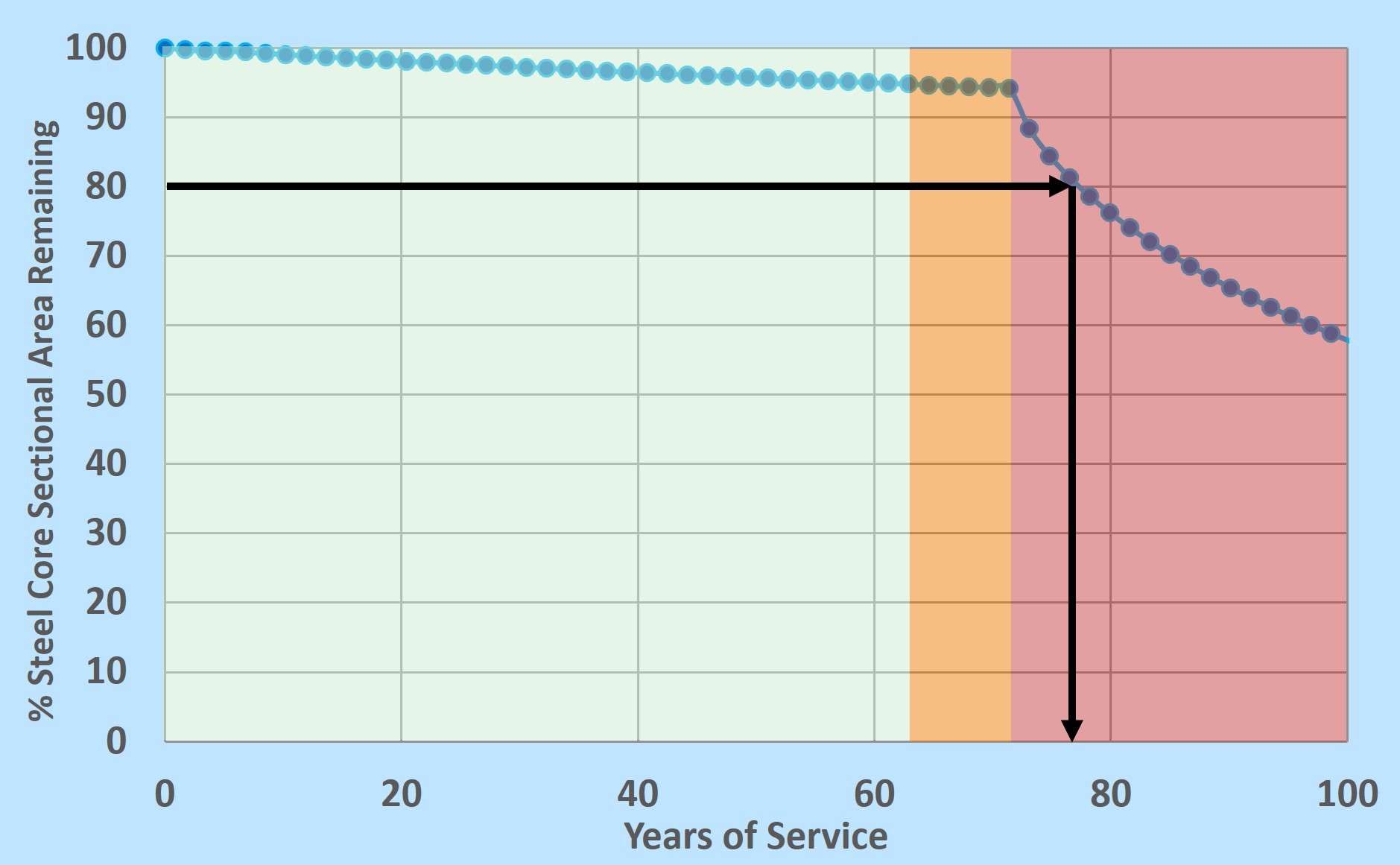

Selection and Application of Conductors for Severe Service Environments: EPRI intends to develop an end-of-life calculator that incorporates the effects of conductor attributes and the surrounding environment corrosivity on the conductor’s durability. This information may be used by a utility to prioritize conductor inspection and select the right conductor for a specific location.

Corrosion Management Reference Book (The Rust Book): This reference book contains asset management information for inspection, assessment, mitigation, and remediation of corrosion on transmission lines. The guidebook contains the fundamentals of corrosion, guidance for inspection and assessment, and a description of mitigation methods that align with the environment. Future sections are intended to be developed to support underground transmission, substations, and distribution.

Advanced Conductors Corrosion Study: This task aims to evaluate the corrosion degradation of advanced conductors, reviewing the materials used in the construction of the conductor. The components used in the construction are then exposed to environmental factors to study the response. Once the components have been evaluated, the assembly is aged in a simulated service environment to study the performance and potential failure mode because of corrosion.

Anticipated Deliverables

| Deliverable | Type | Date |

|---|---|---|

| Aluminum Conductor Steel Reinforced (ACSR) and Aluminum Conductor Steel Supported (ACSS) End-of-Life Calculator | Software | 12/31/2025 |

| All Aluminum Conductors (AAC, AAAC, and ACAR) Corrosion Resistance | Technical Update | 12/31/2025 |

| Conductor Corrosion Condition Assessment | Technical Update | 12/31/2025 |

| Using Greased Conductor for Enhanced Corrosion Protection | Technical Update | 12/31/2025 |

| Corrosion Management Reference Book (The Rust Book) | Technical Update | 12/31/2025 |

Past EPRI Work on Topic

| Product ID | Title | Description | Published Date |

|---|---|---|---|

| 3002021805 | Corrosion Management Reference Book | This technical report will provide information to better understand methods to locate, inspect, assess, and mitigate corrosion. | December 2022 |

| 3002026928 | Conductor Selection and Application for Corrosive Areas | This report highlights the factors governing ACSR and ACSS corrosion. Utilities can use these findings to better select conductors that will withstand severe corrosion areas. | December 2023 |

| 3002021462 | Understanding Conductor and Hardware Corrosion due to Vibration: Fretting Fatigue and Wear | Fretting corrosion has been identified as a mechanism that accelerates the degradation of the galvanized steel core of ACSR and ACSS conductors. | December 2021 |