Objective

The overhead transmission system is facing a challenging time with an aging infrastructure and increased power demands. To deliver safe, reliable, and efficient power transmission, it is important that engineers make the best decisions when selecting, specifying, installing, and maintaining overhead transmission conductors and connectors. This project focuses on performing research to provide effective guidance for member utilities to select, specify, install, and maintain traditional conductors and connectors. Traditional conductors and their connectors include copper (Cu) conductors, all aluminum conductors (AAC), aluminum conductor alloy reinforced (ACAR) conductors, all aluminum alloy conductors (AAAC), and aluminum conductor steel reinforced (ACSR) conductors.

This project aims to understand the performance and degradation mechanisms of traditional conductors and connectors through empirical testing and assessments of components from the field. In addition, this project intends to assess the performance of existing traditional conductor and connector inspection technologies, develop guidelines for inspection, develop acceptance criteria for traditional conductors and connectors, and work to identify and evaluate new inspection technologies. Furthermore, this project aims to evaluate the efficacy of mitigation strategies for degraded conductors and connectors.

Research Value

By performing research on traditional conductors and connectors, this project aims to:

- Increase safety by reducing line drops

- Reduce sustained, unplanned outages because of conductor and connector failure

- Improve reliability by improving inspection and assessment practices

- Optimize spending by appropriate inspection prioritization of assets

- Improve productivity of field personnel with training and field tools

- Improve reliability by selecting the appropriate conductor and connectors for the specific use

- Address the loss of institutional knowledge by providing training

Planned 2025 Research

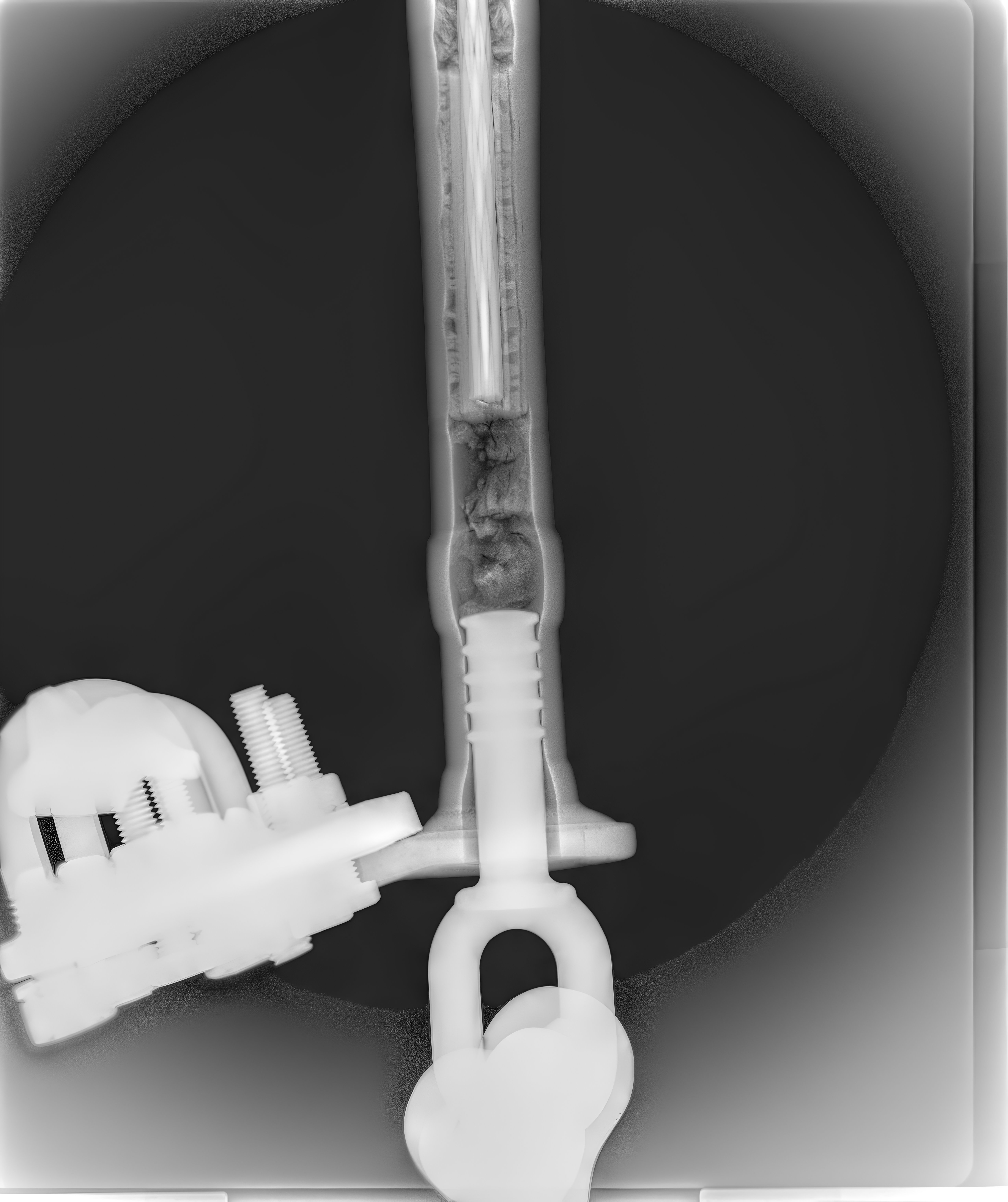

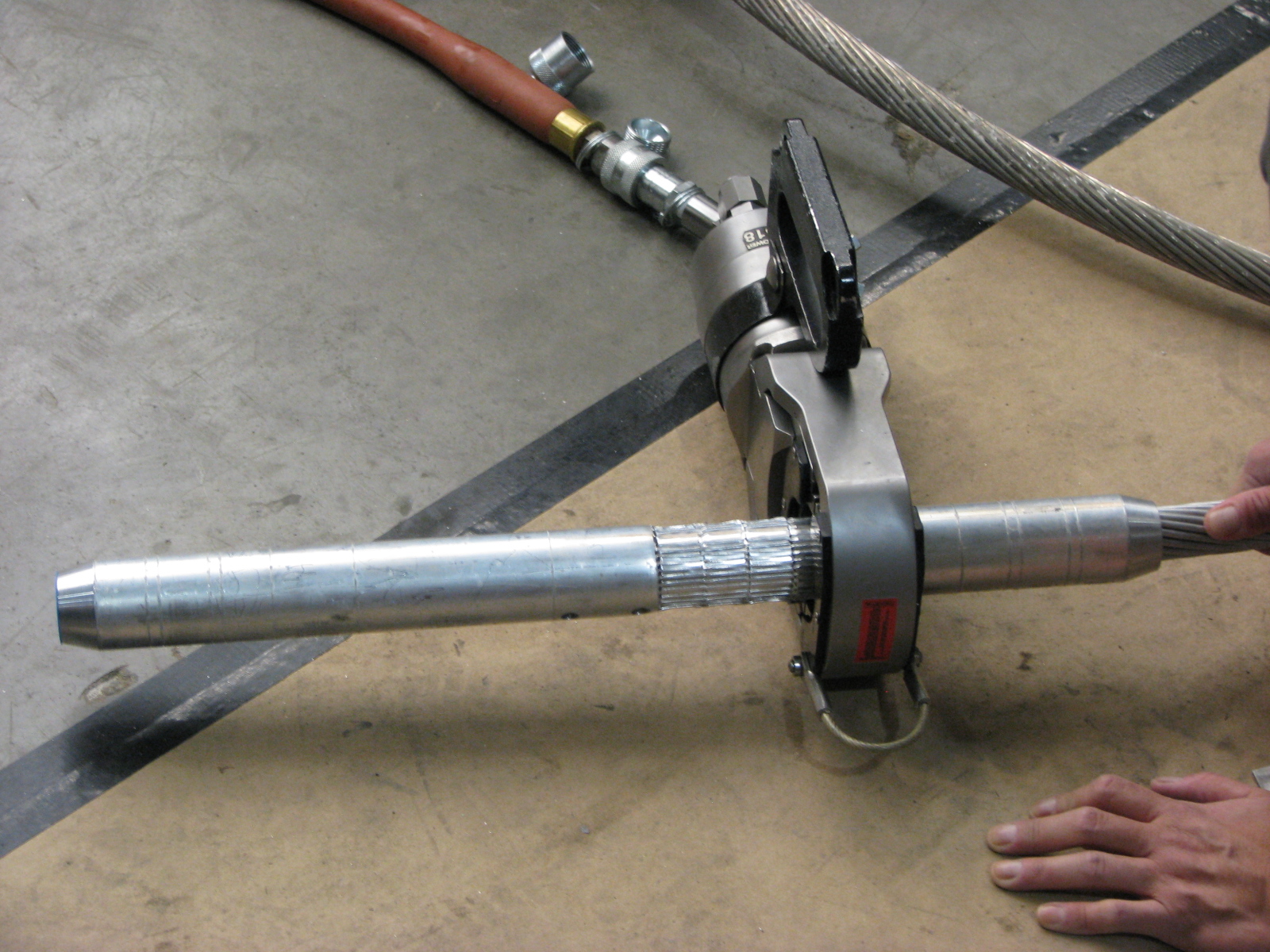

Evaluation of Connector Inspection Technologies. Various connector inspection technologies are expected to be identified, reviewed, and evaluated. EPRI intends to provide updates on different digital radiography devices available for traditional conductors and connectors. In 2025, EPRI aims to include updates on new and emerging inspection techniques as well as a catalog of failure mechanisms for traditional conductors and connectors to the Connector Inspection Guide.

Analysis of Failed or Removed-from-Service Connectors. Connectors that have failed in service or have been removed from service are evaluated in a laboratory to better understand aging and failure modes. Tests may include resistance measurements, thermal responses, infrared (IR) measurements, radiographic analysis, and dissection or mechanical tensile testing to failure. EPRI aims to include and track this information in a database to identify trends in the industry. In 2025, EPRI plans to update the report Evaluation of Aged Connectors.

Degradation of Single-Stage Compression Fittings at 93°C. EPRI has provided guidelines to assist utilities with the inspection and management of line connectors based on previous EPRI empirical testing of traditional conductors and connectors. In 2025, EPRI intends to start testing newly developed single-stage compression fittings for traditional conductors operating at 93°C to understand their performance and degradation mechanisms over a simulated 40-year lifespan.

Guidelines for Management of Connectors. Guidelines help utilities manage connectors through their lifetime, including scheduling of inspections, selection inspection methods, data collection and use, prioritizing, and mitigation strategies. In 202 5, additional acceptance criteria for the various inspection techniques are intended to be included in the published Compression Connector Management Guide.

Effects of Joint Compound Application in Overhead Transmission Compression Connector Performance. Accelerated aging at 93°C of test lines assembled with different amounts of joint compound is to be continued into 2026 to evaluate the impact of joint compound on the thermal and electrical performance of two-stage compression connectors. In 2025, thermal mechanical aging is anticipated to continue on two-stage compression fittings with different amounts of joint compound applied, and data will be shared with the funding members at task force meetings.

Degradation of T-tap Connectors and Installation and Inspection Guidance. This task seeks to outline the types of t-tap connectors, possible degradation mechanisms, and inspection methods. Case studies from field evaluations will be provided to share lessons learned with the funding members.

Anticipated Deliverables

| Deliverable | Type | Date |

|---|---|---|

| Connector Inspection Guide | Technical Update | 12/31/2025 |

| Connector Management Guide | Technical Update | 12/31/2025 |

| Evaluation of Aged Compression Connectors | Technical Update | 12/31/2025 |

| Effects of Connector Compound Application in Overhead Transmission Compression Connector Performance | Technical Update | 12/31/2025 |

Past EPRI Work on Topic

| Product ID | Title | Description | Published Date |

|---|---|---|---|

| 3002027252 | Field Guide: Construction and Inspection of Compression Connectors for Overhead Transmission Lines | This report describes typical applications, compression connector basics, construction methods, common assembly errors, and inspection methods. In addition, it provides a list of relevant technical and training resources. | 05/08/2023 |

| 3002027253 | Field Guide: Infrared Thermography for Overhead Transmission Lines—Insulators, Compression Connectors, Overhead Ground Wire, and Surge Arresters | This guide is designed to assist both skilled IR thermographers and experienced engineers in improving measurement accuracy. | 05/08/2023 |

| 3002027267 | Field Guide: Inspection of Conductors for Overhead Transmission Lines | This guide provides a general, field-deployable resource for utility professionals who are engaged in the inspection and assessment of overhead transmission lines. | 05/08/2023 |

| 3002026952 | Guidelines for Connector Inspection: Update on Mechanical Effects of Improper Installation of Two-Stage Compression Connectors | Various inspection techniques and methods for connectors are discussed, including the benefits and challenges of each technique. This guide covers visual inspection, dimensioning, thermal measurements, infrared thermography, resistance measurements, and radiography of compression connectors. | 12/20/23 |

| 3002026953 | Connector Management Guide: Software Application Solutions and End of Life Model Development | This technical update describes how to create an inspection and management plan for compression connectors. | 11/13/23 |

| 3002026955 | Evaluation of Aged Compression Connectors: Evaluation of ACSS Dead Ends with Insufficient Filler Compound, 230 kV | This document provides an overview of three different types of compression connectors, describes factors that contribute to compression connector failures, presents the EPRI process for evaluating field-aged connectors, and catalogs results from aged compression connector evaluations. | 10/25/2023 |

| 3002026957 | Effects of Connector Compound Application in Overhead Transmission Connector Performance | EPRI has set out to review, survey, and test connector compounds that have been in the market in the past and that are currently being produced to better understand the impact of connector compounds on the performance of overhead transmission connectors, evaluate the compounds on the market, understand the degradation of connectors using connector compounds, and understanding how to apply connector compounds most effectively. | 12/19/2023 |