P35.005: Ductile Iron and Composite Structures

Objective

With ever-increasing pressures on the supply chain, utilities are becoming more interested in alternative materials to construct transmission lines. The objective of this research is to increase the knowledge base of members on the use of alternative materials of transmission structures, with specific focus on mechanical and electrical performance as well as economic considerations.

Two leading alternative materials in this space include ductile iron and composite materials. EPRI’s research aims to improve utility expertise in the design, application, performance characteristics, degradation modes, and future maintenance requirements of these nontraditional materials. Knowledge is generated through collaboration with utility members, structure manufacturers, and, most importantly, through laboratory testing completed at EPRI facilities.

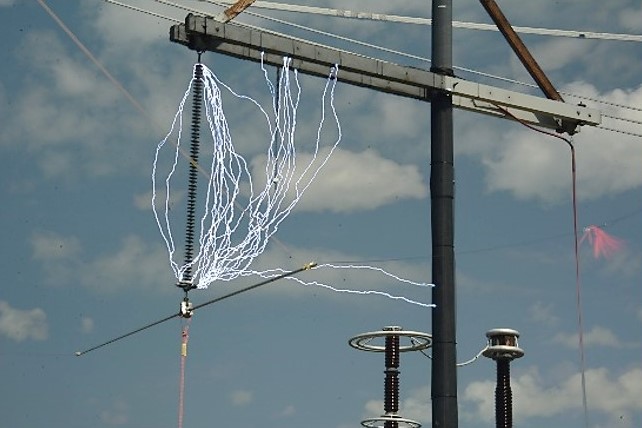

Utility poles manufactured from glass fiber-reinforced polymer (GFRP) composites are employed as alternatives to traditional steel and wood structures. In addition, composites crossarms are widely gaining popularity because of their low weight and high durability. Despite continuing refinements in material composition and manufacturing techniques, composite products have a fairly short history in electric utility service. There is a need to fully understand the material attributes as well as failure and degradation modes, particularly at high voltages. This body of knowledge is supported by identifying the initiation mechanisms leading to the degradation and failure modes of the material and the aging rates of that material.

Another material being evaluated for utility structures is ductile iron. This material has been used for underground water piping for over 100 years and is therefore well established for that application. Utility poles manufactured from ductile iron were first installed in the United States in 2008 and have provided good service, but research is needed to improve understanding of the material’s degradation and mechanical failure modes. EPRI aims to help utilities leverage some of the inherent advantages of ductile iron, such as its corrosion resistance and durability relative to wood, while controlling for potential disadvantages.

Research Value

Research on ductile iron and composite structures aims to:

- Increase reliability in electrical service through the application of high-reliability structure materials

- Increase public safety by reducing the risk of adverse events caused by utility pole failures

- Improve utility structure aesthetic through the use of engineered structure materials

- Lower life-cycle costs and increased system reliability by leveraging the advantages of ductile iron and composite structures

- Improve confidence when applying ductile iron or composite technology

- Increase understanding of performance characteristics and degradation modes of ductile iron and composite materials

Planned 2025 Research

Composite Structures Application Guide Update. Over the last several years, EPRI has been producing an application guide for composite structures built on research performed in this project. The guide covers topics such as composite pole and crossarm manufacturing, degradation modes, installation, and maintenance. In 2025, EPRI plans to issue an update to this guide to incorporate highlights from recent research into composite structures. Updates may include the creation of design recommendations for composite structures and results from artificial aging tests on composite materials.

Full-Scale Mechanical Testing of Ductile Iron Utility Poles There exists no industry standard methodology to quantify the mechanical capacity of ductile iron utility poles. Although some manufacturer testing has been completed, engineers must have a high degree of confidence in the mechanical strength of ductile iron poles to ensure that they meet the appropriate loading criteria. EPRI plans to initiate a series of full-scale loading to failure tests on ductile iron poles to understand the reliability of published strength values, variability in strength, and failure modes.

Ductile Iron Structure Application Guide Update. In parallel to performing tests on ductile iron poles, EPRI is undergoing a multi-year effort to develop an application guide for utility engineers. In 2025, an update to this guide will be produced, incorporating findings from full-scale mechanical tests. Other additions may include an overview of current ductile iron pole manufacturers and design recommendations.

Optimal Pole Material Selection Guide Update. In partnership with P35.007, EPRI’s Line Design research project, a guide is being produced to compare the five primary materials used for utility structures: wood, steel, concrete, fiber-reinforced plastic (FRP) composites, and ductile iron. In 2025, EPRI aims to produce representative structural designs of all five materials under various loading conditions. This will help engineers make more informed decisions to select an optimal pole material for their application.

Access to Information Exchange Sessions on Ductile Iron and Composite Structures. In 2025, EPRI plans to host two online information exchange sessions covering ductile iron and composite structures. The goals of these sessions will be to encourage inter-utility dialog on the use of these materials and help engineers network with peers in the industry. Session content may include utility application case studies of ductile iron and composite structures, perspectives from structure manufacturers, and identification of research priorities for utilities.

Anticipated Deliverables

| Deliverable | Type | Date |

|---|---|---|

| Composite Structures Application Guide | Technical Update | December 2025 |

| Ductile Iron Structure Application Guide | Technical Update | December 2025 |

| Optimal Pole Material Selection Guide | Technical Update | December 2025 |

Past EPRI Work on Topic

| Product ID | Title | Description | Published Date |

|---|---|---|---|

| 3002026961 | Design Methodology for Composite Poles as Anti-Cascading Structures | A design method and series of case studies on the selection of composite poles for longitudinal cascading resistance. | December 2023 |

| 3002021480 | Composite Structures Application Guide | An application guide covering the selection, application, inspection, and maintenance of composite utility structures | December 2021 |

| 3002026963 | Effects of Accelerated Aging on Composite Pole Material Samples | Results from accelerated aging testing on composite material samples, simulating environmental degradation | November 2023 |