Objective

Transmission asset owners can raise the power transfer capacity of a transmission line by increasing the line current. This increase in line current may lead to an increase in conductor operating temperature. An elevated conductor temperature could result in reduced conductor ground clearance (increased sag), loss of conductor strength, and damage to connectors and other attached hardware accessories. In addition to these mechanical effects, the elevated temperatures can impact the line corona performance, resulting in values that exceed the utility’s design specifications.

Research is needed to:

- Understand premature failures of conductors and conductor accessories because of thermal aging from high-temperature operations

- Determine and evaluate the mitigation and remediation options for high-temperature operation

- Understand the high-temperature effects on corona, thermal, and other models used in evaluating electrical effects, heat-transfer capability, and other performance indicators of an overhead line

- Determine and verify the mechanical effects of high-temperature operation on conductor performance

The main objectives of this research project are to help utilities raise transmission line capacities (through increased current) safely, reliably, and with confidence and to provide a technical basis that supports utility decisions on operating lines at elevated temperatures. These objectives are accomplished with research to evaluate the risks of raising an overhead line to a higher temperature; understand the application and performance of using mitigation methods for increasing the operating temperature of an overhead line; and evaluate the electrical, mechanical, and thermal performance of overhead line conductors, connectors, and other attached hardware accessories more accurately. Utilities can then establish internal guidelines for the high-temperature operation of their overhead lines.

Research Value

Through emperical studies, collecting utility experiences, and developing models, research in high-temperature operation of overhead lines can lead to a:

- Reduction in capital and operational costs by maximizing existing transmission infrastructure

- Increased safety and reliability by using mature models to determine the effects of increasing current on the existing system

- Reduction in operational cost by understanding where limiting conditions may be located to prioritize inspection and remediation solutions

Planned 2025 Research

This project undertakes tasks to develop the required information to make effective decisions when operating lines at elevated temperatures. These tasks include:

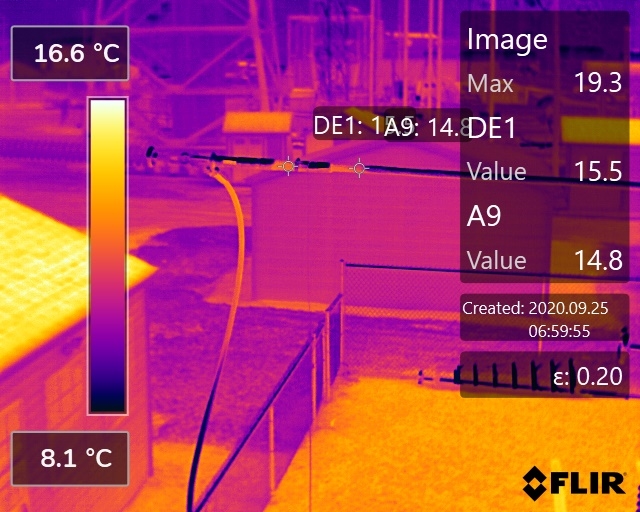

Evaluation of the Effect of Emissivity on Conductor-Connector Thermal Performance: This task intends to undertake research to understand the thermal effects of having a high-emissivity surface on conductor-connector systems. A high-emissivity coating will be applied to aged conductor and new connectors to evaluate their performance and durability. At the end of the thermal cycling, the thermal profiles of the high-emissivity connectors are planned to be compared to noncoated conductor-connector systems. Mechanical tests may also be performed to determine the residual strength after the thermal mechanical cycling.

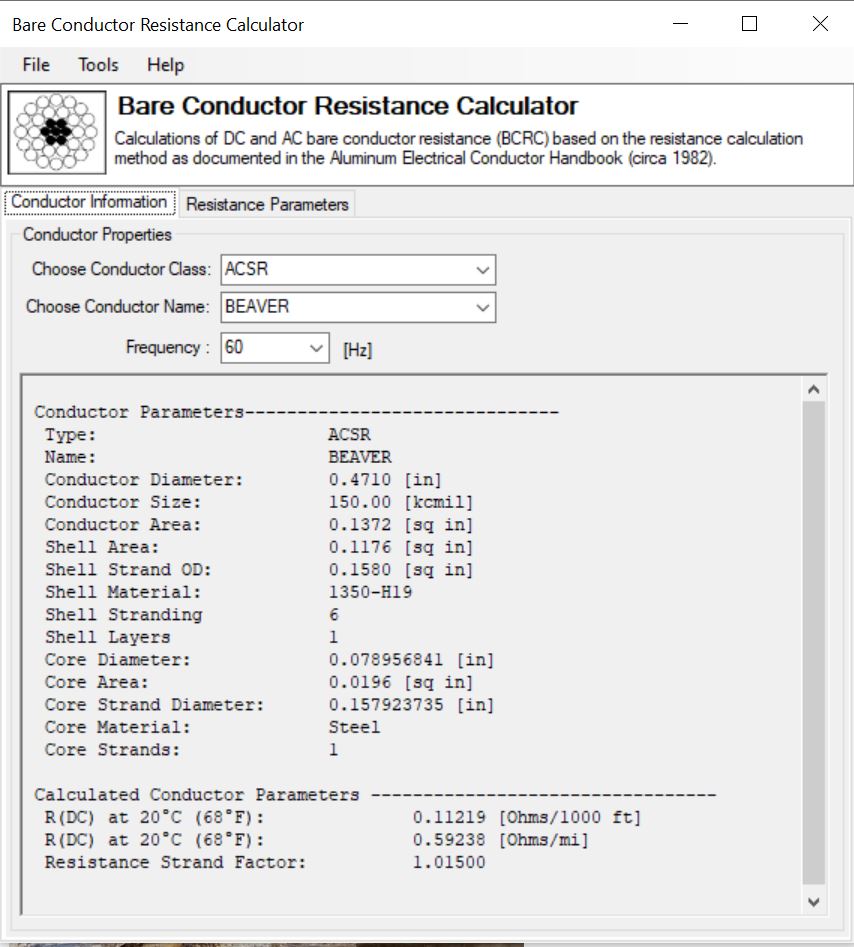

HTC Matrix Software Tool for Evaluating High-Temperature Operations: The High-Temperature Conductor (HTC) Matrix was developed as a repository for all the high-temperature overhead conductor research conducted by EPRI. The HTC Matrix includes several calculators. For 2025, the intent is to update the software for improved usability and accessibility as well as transfer one calculator to the web-based platform.

Guide for High-Temperature Operation: This task intends to update the guide developed to assist utilities in safely operating lines at higher temperatures. Each year, a new chapter could be added or an existing chapter updated. In 2025, case studies from utilities are expected to be collected and published.

Evaluating Connectors at High Temperature: A variety of overhead transmission connectors are used, including quadrant clamps, preformed wraparound connectors, and compression connectors. In addition, new single-stage compression connector designs are entering the market. This task intends to evaluate the performance of these connectors operating at elevated temperatures. In 2025, we anticipate continuing our research into the effects of high-temperature operation on bolted connectors.

Corrosion at Elevated Temperatures: Corrosion rates increase at elevated temperatures; however, those rates have not been quantified. This task sets out to understand the increase in corrosion rate with elevated temperature. In 2025, the plan is to continue work on the development of equations to model corrosion rates at elevated temperatures.

High-Temperature Effects on Conventional Conductor-Connector Systems: This task sets out to understand the degradation mechanisms of conventional conductor-connector systems, such as copper, all aluminum conductor (AAC), all aluminum alloy conductor (AAAC), aluminum conductor alloy reinforced (ACAR), and aluminum conductor steel reinforced (ACSR). In 2025, the project aims to develop equations representing the annealing behavior of copper using the results obtained from the 2024 empirically obtained data.

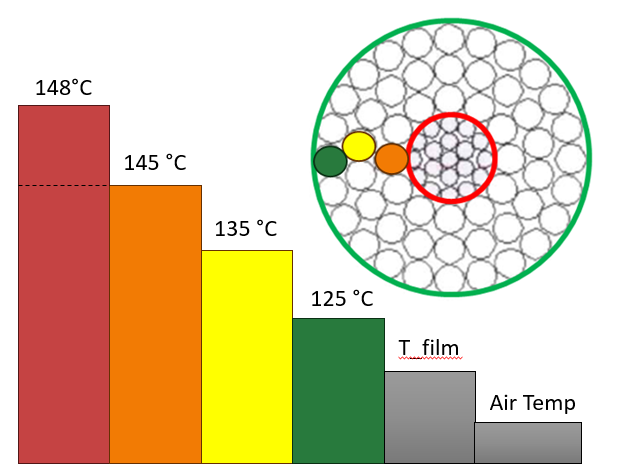

Radial Conductor Temperatures and Ratings: Because of the fundamental properties of heat transfer, transmission conductors are hotter at the core than at the outer surface. The increased core heat can lead to line sag being greater than projected in software tools. A combination of literature review, modeling, and lab testing can be used to establish correction factors to prevent utilities from exceeding clearance requirements or identifying the required ampacity derates if no action is taken.

Anticipated Deliverables

| Deliverable | Type | Date |

|---|---|---|

| High-Temperature Conductor (HTC) Matrix | Software | December 2025 |

| Guide for High-Temperature Operation of Overhead Lines | Technical Update | December 2025 |

| Corrosion at Elevated Temperatures | Technical Update | December 2025 |

| High-Temperature Effects on Overhead Transmission Accessories | Technical Update | December 2025 |

Past EPRI Work on Topic

| Product ID | Title | Description | Published Date |

|---|---|---|---|

| 3002027104 | High-Temperature Conductor (HTC) Matrix: v13 | EPRI’s HTC Matrix software is a Windows application designed to provide the user with quick and directed access to the information developed under several EPRI projects investigating the effects of high-temperature operation of conductors. | November 2023 |

| 3002027106 | Guide for Operating Overhead Lines at High Temperatures: Mitigation Strategies | This report provides technical information and research data to assist users in evaluating the option of raising overhead transmission line capacities by increasing the current and therefore the conductor temperature. | December 2023 |

| 3002027109 | Overhead Transmission Connectors Operating at High Temperature | This report will summarize EPRI’s research on the effects that high-temperature operations have on the performance of overhead transmission connectors to enable utilities to make informed decisions when increasing the ratings for their lines. | December 2023 |

| 3002027111 | High-Temperature Conductor (HTC) Matrix Practical Application: Examples of Utilizing HTC Matrix for Elevated Temperature Operation Analysis | This report’s primary aim is to educate engineers on how to navigate the HTC Matrix software package to perform analysis related to elevated temperature operations of overhead transmission lines. | November 2023 |