P35.015: Advanced Conductors and Connectors

Objective

Advanced conductors (which include high-temperature, low-sag [HTLS] conductors) offer the advantages of higher current capacity, potentially lower conductor sag, and lower line losses than conventional aluminum conductor steel reinforced (ACSR) conductors. Knowledge of the long-term performance of advanced conductors is limited, particularly for newly developed products. In addition, there is a need for information on the specification, selection, procurement, application, installation, and maintenance of advanced conductors. This project intends to address knowledge gaps and give transmission owners and operators confidence in applying this technology.

The key objective of this research is to help transmission engineers apply this technology with confidence by:

- Providing guidance on the selection and specification of advanced conductors

- Developing test protocols to compare different advanced conductors’ performance and durability

- Performing empirical studies to understand the performance and degradation mechanisms of advanced conductors

- Performing laboratory evaluations of inspection technologies for advanced conductors

- Performing empirical studies to refine installation guidance

- Collecting utility insights to benefit from lessons learned

Research Value

Anticipated benefits to the public and funders are to:

- Increase safety by providing guidance on the appropriate methods to inspect and maintain advanced conductors and their connectors

- Increase safety and reliability by providing guidance on the best installation methods for advanced conductors and their connectors

- Provide the technical basis for improved decision making in the selection of advanced conductors and their connectors

Planned 2025 Research

This project addresses critical issues related to the long-term performance of HTLS conductors by undertaking specific tasks:

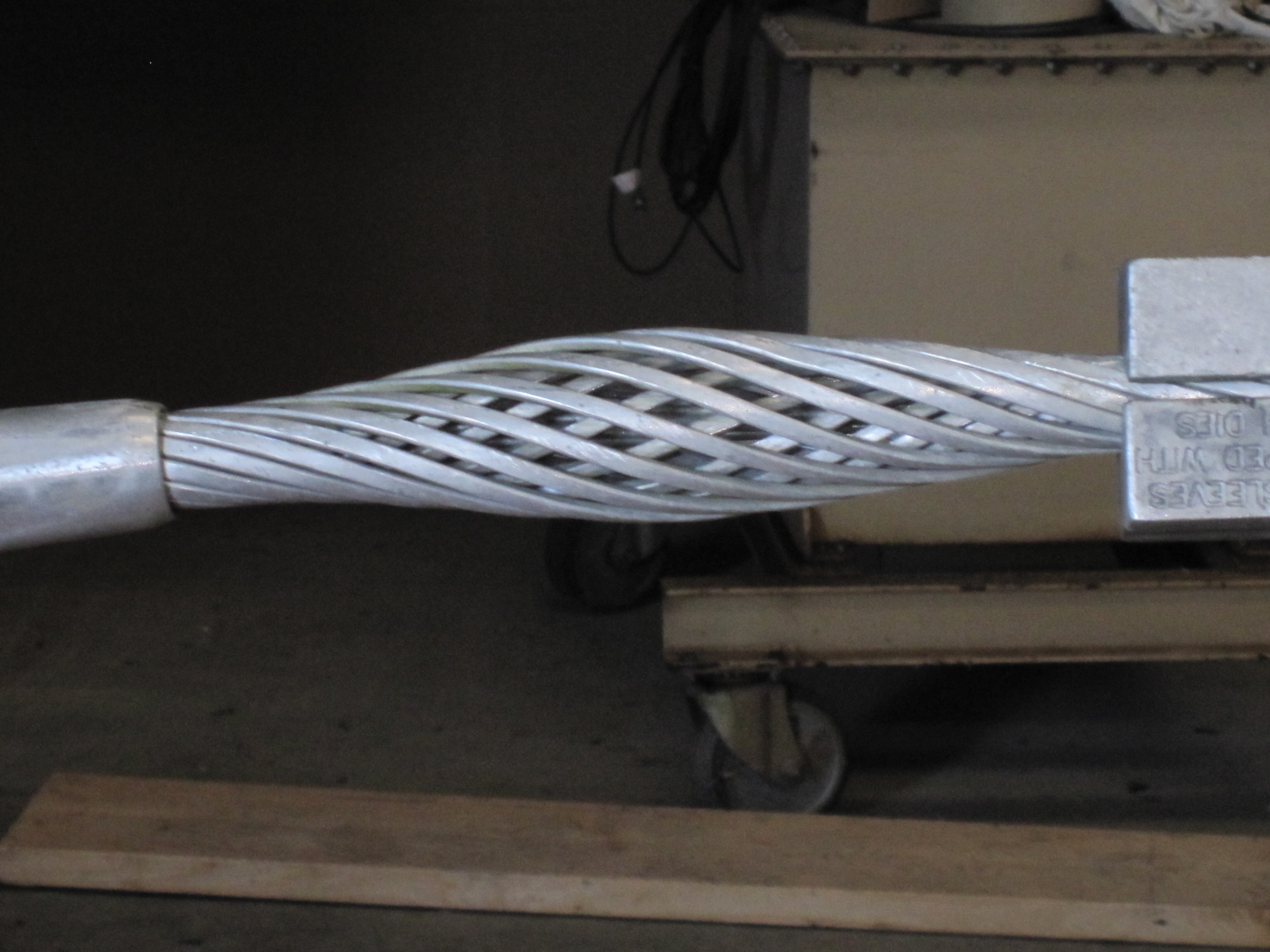

Guidelines for the Installation of Advanced Conductors: Generally, composite core conductors have different handling and installation requirements than traditional steel core conductors. Typical line installation crews are not as familiar with the HTLS installation requirements compared with the traditional ACSR conductors. Most of the premature HTLS failures have occurred because of improper installation practices. This task intends to compile best practice guidelines based on manufacturer recommendations and utility experiences.

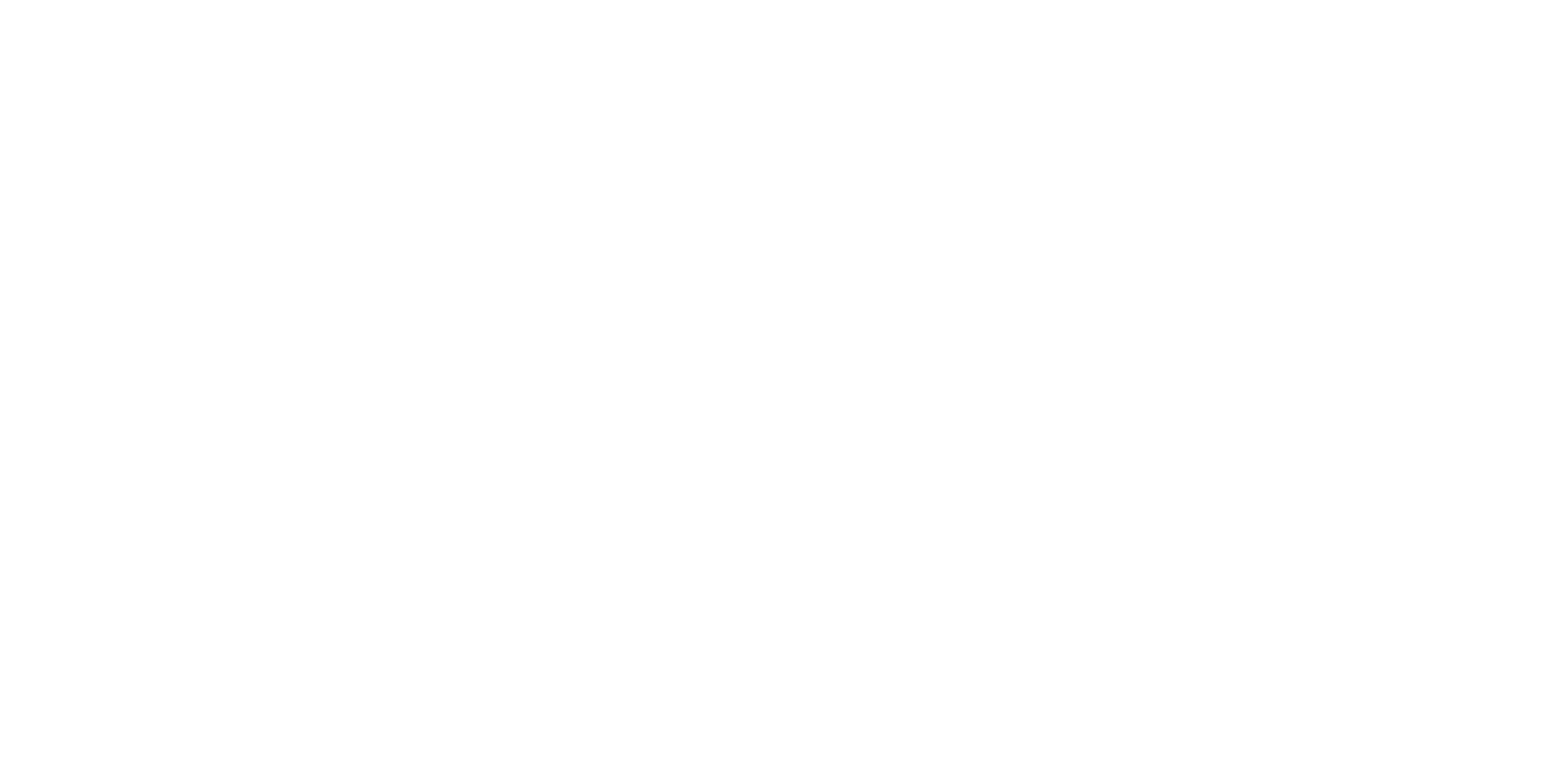

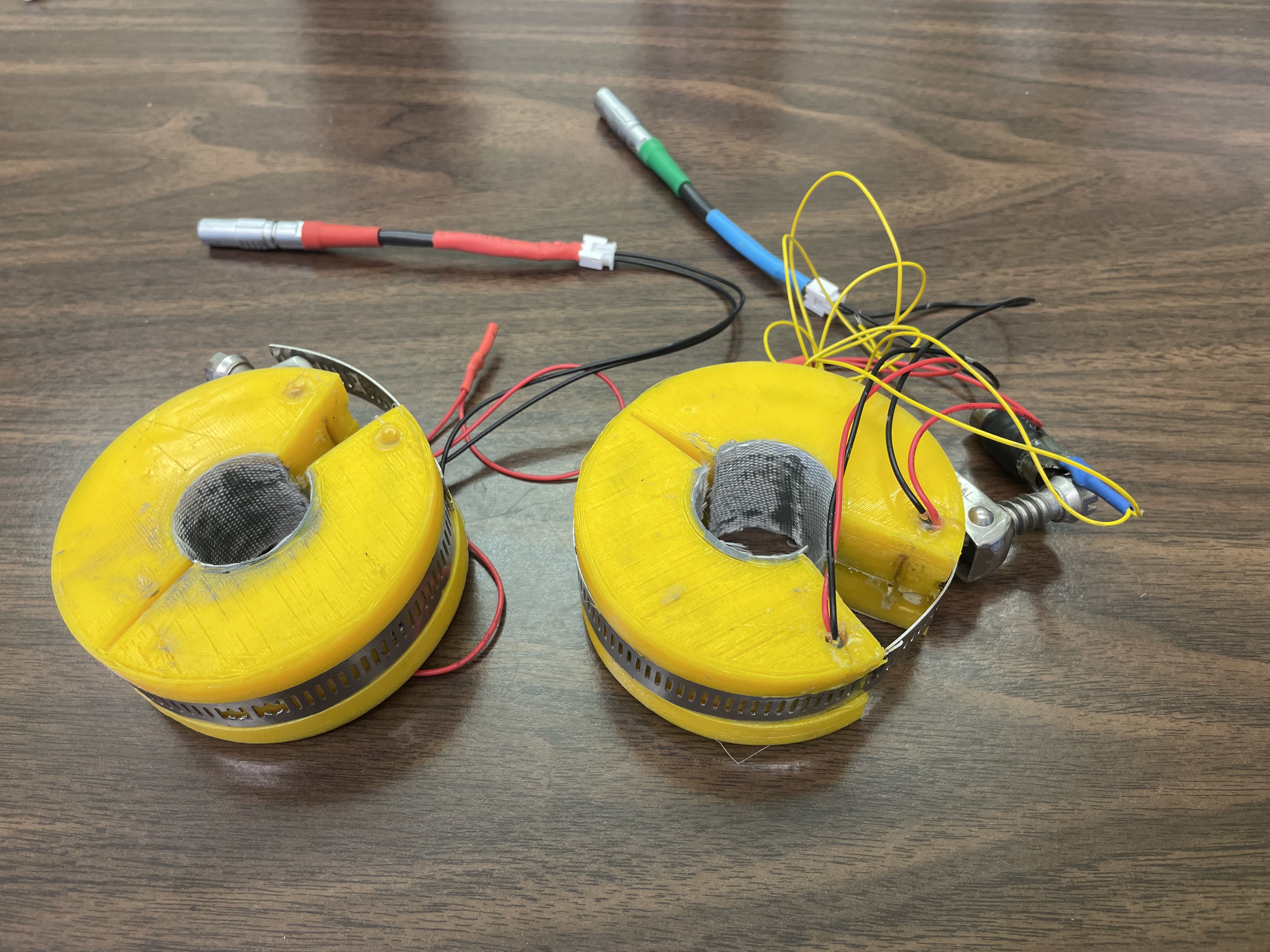

Inspection of Advanced Conductors: Composite core conductors generally are more fragile than traditional conductors. There may be a need to evaluate the condition of conductors after installation, impact events, or extreme weather. In addition, as many lines using advanced conductors start to age, there is a need to inspect and assess the core condition. In 2025, this task intends to further evaluate the inspection technologies tested in 2024.

Qualification Testing of Carbon Core Conductors: Because carbon core advanced conductors have only recently been developed, there is a lack of information on how utilities can qualify them for application on their transmission systems. In 2025, this task intends to test and document the results of a TS carbon core conductor. This information can be used by utilities to properly evaluate these advanced conductors.

Identification of Best Practices for the Maintenance of Advanced Conductors: Advanced conductors can operate at temperatures greater than 150°C. These temperatures could pose a risk for utility workers and the tools they use. This task intends to evaluate the effects of high temperature on workers and the tools they use as well as investigate the effects of tools on the conductors.

Environmental Effects Impact on the Performance of Advanced Conductors: This task intends to investigate how exposure to various environmental factors might affect the electrical and mechanical performance of HTLS conductors—specifically, non-steel-core HTLS conductors. The factors intended to be evaluated include fire, tree falls, hurricanes, and tornadoes.

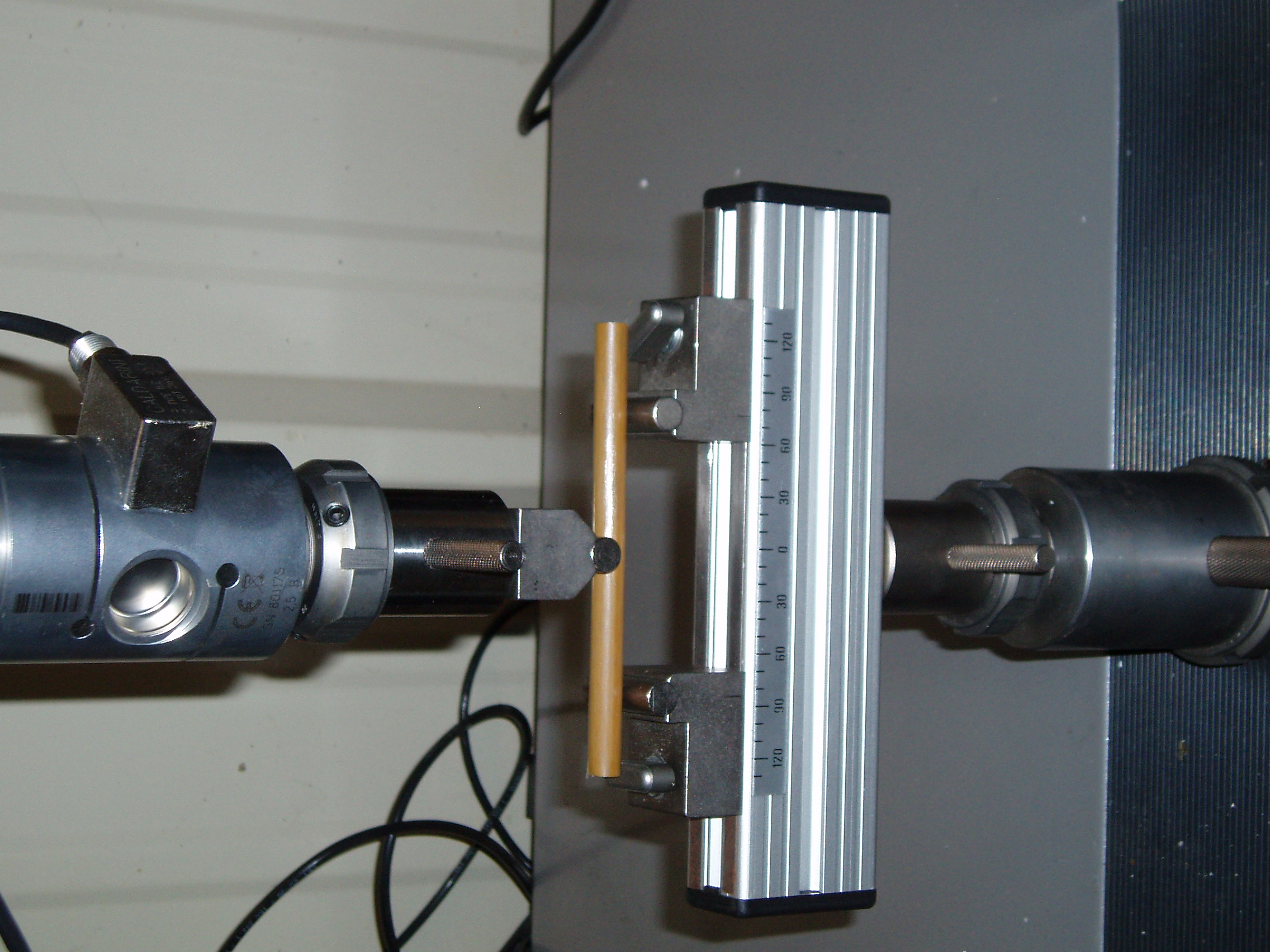

Development of a Guide to Safe Design Tension for ACSS Conductor: Determining a safe conductor tension is a multi-faceted problem that requires understanding of the self-damping performance and fretting fatigue endurance of a conductor. This initiative, which is a collaborative effort with P35.007, is focused on helping solve this problem initially for ACSS conductor because its self-damping and fatigue properties vary significantly from those of ACSR conductor. In 2025, full-scale vibration testing of an advanced conductor is planned.

Evaluation of Field-Aged Conductors and Connectors: This task intends to provide an update on the results of evaluations performed on aged HTLS conductors. Through this evaluation, it is envisioned that a better understanding of the aging impact on the electrical and mechanical performance of these conductors may be obtained. In 2025, a report detailing these evaluations is intended to be updated.

Development of Guidelines for the Specification, Selection, and Application of Advanced Conductors: This task develops a guide (which is intended to be updated each year) to assist utilities in the proper selection and application of advanced conductors. The following information is intended to be included:

-

Field and test experiences with different advanced conductors

-

Application case studies

-

Documentation and characterization of various types of conductors

-

Review and development of technical specifications of the different advanced conductor types

-

Review of the various standards associated with advanced conductors

Anticipated Deliverables

| Deliverable | Type | Date |

|---|---|---|

| Guide for the Selection and Application of Advanced Conductors | Technical Update | December 2025 |

| Evaluation of High-Temperature Effects on Maintenance Practices | Technical Update | December 2025 |

| Inspection of Advanced Conductors | Technical Update | December 2025 |

| Carbon Core Conductor Qualification Testing | Technical Update | December 2025 |

| Environmental Effects Impact on the Performance of Advanced Conductors | Technical Update | December 2025 |

Past EPRI Work on Topic

| Product ID | Title | Description | Published Date |

|---|---|---|---|

| 3002027132 | Mechanical Testing of a New ACSS Connector (Solo) | This report details the testing and results obtained from the ambient and elevated temperature tests on the Solo ACSS connectors (splices and dead ends). | December 2023 |

| 3002024464 | Summary of Qualification Tests Performed | This report summarizes the carbon fiber core conductor qualification tests performed from 2008. | December 2022 |

| 3002021583 | ACSR and ACSS Self-Damping Performance | This report presents the self-damping performance of Drake and Thrasher ACSS and ACSR conductors and discusses the design rules used for mitigating conductor motion by limiting the tension in the conductor. | December 2021 |