P36.002: Extruded Dielectric Cable Systems

Objective

Utilities rely on extruded dielectric cable systems to meet growing demands for new underground transmission lines. This project intends to address several key research issues, including specific goals:

- Improving engineering-based design and installation procedures to accommodate electrical, mechanical, and thermal requirements for long-term performance, considering thermo-mechanical behaviors of cables and accessories as well as corrosive environments of buried or in-manhole components.

- Developing effective inspection and monitoring methods for cable system condition assessment.

- Achieving a better understanding of cable and component aging, failure mechanisms, and end-of-life criteria. Underground transmission engineers, designers, and managers can use the guidelines, methods, and technologies developed or assessed in this project to improve productivity and reduce costs of designing, installing, commissioning, testing, operating, and maintaining extruded dielectric cable systems. Engineers may use the improved understanding of the behavior of extruded dielectric cables under normal and emergency loading scenarios plus analytical or software-based tools to achieve effective and economical system designs. Operators and maintenance departments can deploy new inspection and monitoring methods and tools to obtain real-time and near-real-time information on cable system conditions.

Research Value

The new materials, devices, and methods produced in this project could improve the performance of extruded dielectric transmission cable systems to meet power system safety, reliability, and maintainability requirements and to contribute to improved technical standards. For example:

- Full-scale laboratory testing may validate and improve theoretical understanding of the thermo-mechanical behavior of extruded dielectric transmission cables. The results would support improved specifications and standardized designs, leading to higher system reliability, fewer circuit outages, and lower life-cycle costs.

- Development and deployment of advanced inspection and monitoring techniques may assist in asset management, improve utility operation efficiency, and increase system reliability.

- Investigation of corrosion inspection, assessment, and remediation methods and techniques for cable components in underground vaults addresses this emerging issue and may improve the design, inspection, maintenance, and protection of these components.

- Laboratory testing can deepen the industry’s understanding of system performance and help determine the end-of-life criteria of the system.

Planned 2025 Research

This project investigates methods and technologies for extruded dielectric transmission cable systems. Solutions are applicable to design, selection, installation, commissioning, testing, operation, and maintenance of these systems. The project seeks to answer research questions and address industry issues through the following activities:

Laboratory testing to validate engineering design models.

Laboratory testing to understand failure mechanisms and end-of-life.

Development and evaluation of innovative inspection and assessment tools, methods, and technologies.

Laboratory testing and field demonstration of developed or available diagnostic methods.

Anticipated Deliverables

| Deliverable | Description | Date |

|---|---|---|

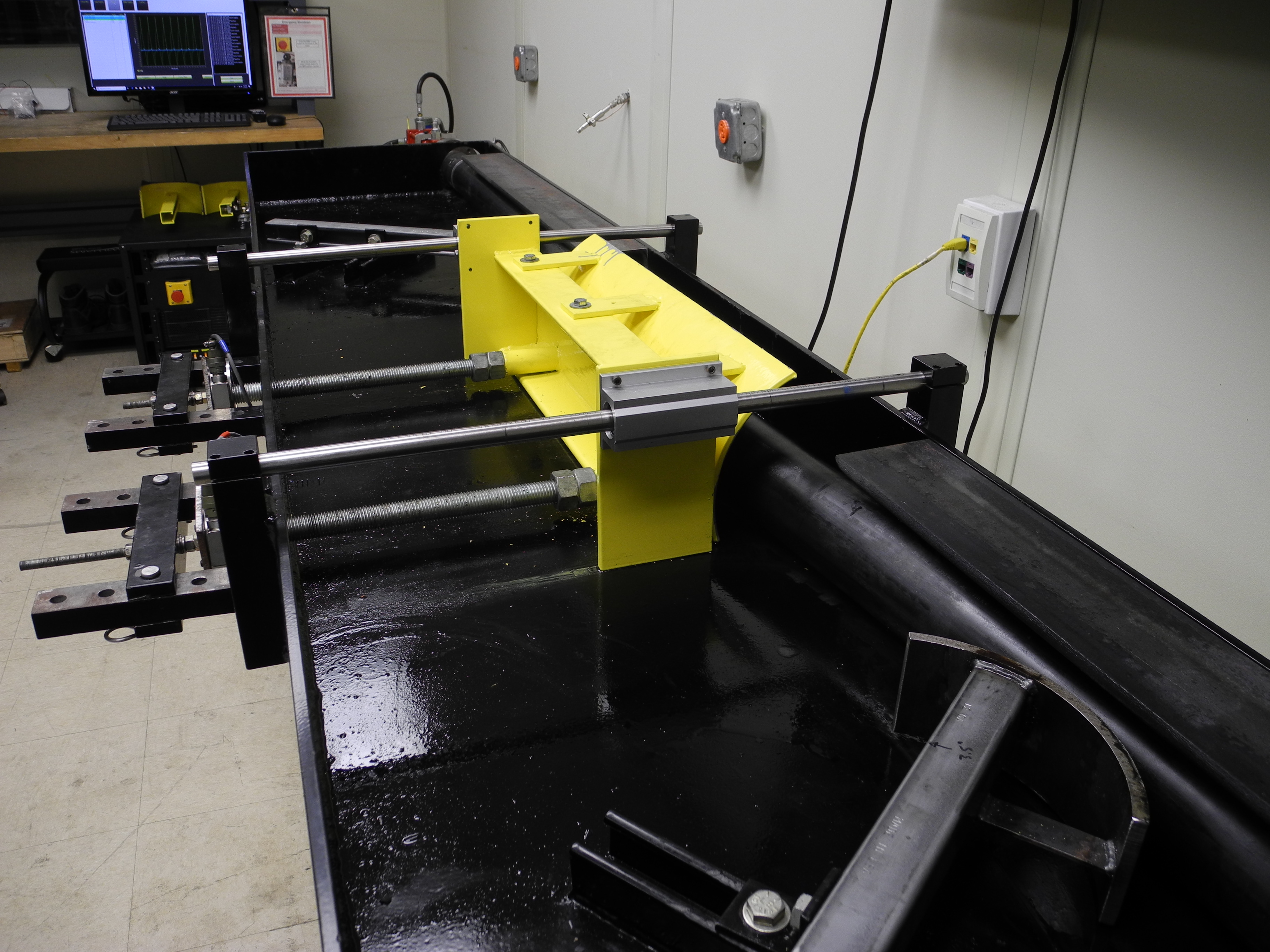

| Guidelines for Thermo-Mechanical Design of Extruded Dielectric Cable Systems (reports) | This multi-year task builds on and continues EPRI’s prior research in laboratory verification of thermo-mechanical behavior of extruded dielectric cables in ducts, pipes, and manholes. Multiple volumes of reports include development of a validated source of practical engineering knowledge to assist cable engineers in designing extruded dielectric cable systems with respect to their thermo-mechanical effects. The reports cover design principles, cable mechanical parameter measurements, finite element analysis modeling, engineering software tools, full-scale laboratory validation, applications at utility sites, and subject matter training. | December 2025 |

| Advanced Sensors and Inspection Techniques for Extruded Dielectric Transmission Cable Systems (report) | This multi-year task is a continuation of the study on advanced sensors and monitoring techniques for inspection of cable system condition and operational status. The task covers developments of test rigs and performs tests to evaluate the effectiveness of available technologies and to demonstrate emerging technologies. | December 2025 |

| Aging Characteristics of Extruded Dielectric Cable Systems and Components (report) | Many extruded dielectric cable circuits are approaching 30–40 years in service. The industry needs an approach to study their life management and expectancy. This task started as a series of laboratory experiments to better understand extruded dielectric cable system aging and failure mechanisms, and has since expanded into three different tests:

|

December 2025 |

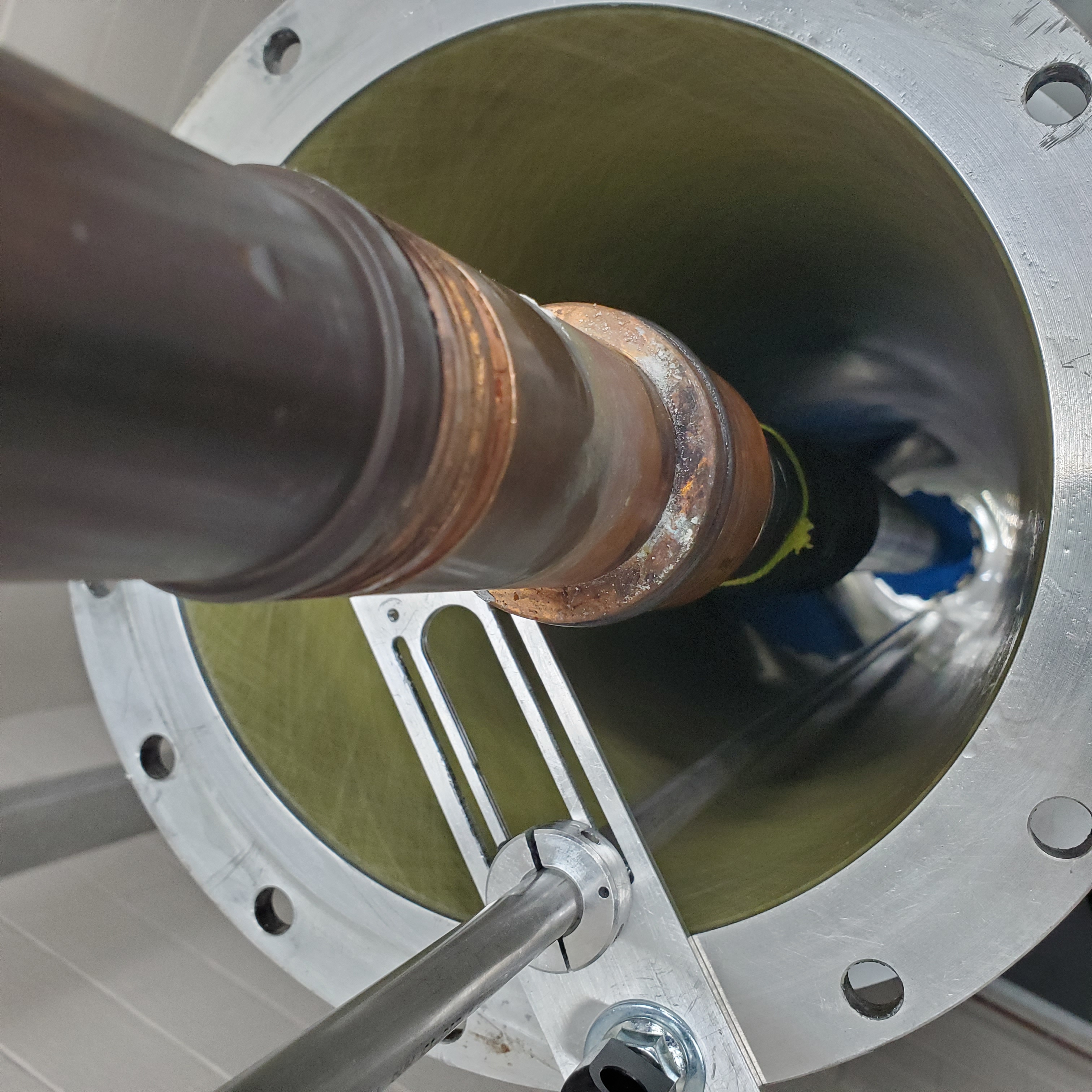

| Underground Transmission Vault Corrosion: Inspection Assessment and Remediation (report) | This task addresses common corrosion issues within underground extruded dielectric cable joint vaults. The report discusses corrosion mechanisms within the vaults and provides inspection and assessment results on components within the vaults. It also provides remediation recommendations based on results of field inspections and laboratory testing. | December 2025 |

| Asset Vintage Guide and Technology Review of Extruded Dielectric Cable Systems (report) | How an asset degrades and fails is often dependent on how the asset was designed and manufactured. This task develops and updates vintage information for component materials, design, manufacturing, and other known issues of extruded dielectric cable systems. This task also provides a state-of-art technology review to assist utility cable users in making engineering decisions for reliable and cost-effective in-service operations. The report captures evolving technologies, success and failure experience, and lessons learned to enforce the needs for continuous vigilance during design, manufacturing, and installation processes of both cables and accessories. | December 2025 |

| Product ID | Title | Description | Published Date |

|---|---|---|---|

| 3002027208 | Experimental Verification for Thermo-Mechanical Models for Cross-Linked Polyethylene Cable in Pipes and Ducts | Results on full-scale verification tests for EPRI thermo-mechanical models of cross-linked polyethylene (XLPE) cable in pipes and ducts. Cable constructions include 345 kV, 4000 kcmil conductor, with corrugated aluminum sheath, and 230 kV, 3000 kcmil conductor, with corrugated copper sheath. | 2023 |

| 3002027212 | Mechanical Bending Test Rig for Extruded Dielectric Transmission Cables | Describes efforts in developing an EPRI bending rig and reports additional results of performed tests. This test rig determines aging performance by mechanical bending of extruded dielectric transmission cables. | 2023 |

| 3002027215 | Quality Guidelines for Grouting Procedures for Large Casings Used for Transmission Cable Systems | Utility experiences with grouting and steps required to properly design and install high-quality grouts. | 2023 |

| 3002021317 | Transmission Extruded Dielectric Cable Sheath Bonding System – Equipment Design and Performance | Guideline document for sheath bonding system and equipment design, performance, and operation and maintenance practices. | 2021 |

| 3002021319 | Guide for Application of Distributed Fiber Optic Temperature Sensing to Underground Power Cables | Reports additional results on a walk-through of setting up a distributed temperature sensing device, required calibrations, follow-up testing, and measurement process. | 2021 |

| 3002019121 | Finite Element Analysis for EPRI Thermo-Mechanical Tests of Aluminum Corrugated, Copper Corrugated, and Lead Sheath Cables | Provides results of finite element analysis modeling of cables of different metallic sheath designs, based on mechanical parameters of axial stiffness (EA) and bending stiffness (EI) as extrapolated from previous EPRI measurements. | 2020 |

| 3002012436 | Mechanical Parameter Testing of Extruded Dielectric Transmission Cables | Describes mechanical parameter test procedures and results obtained on samples of a 3000-kcmil copper conductor cable with corrugated copper sheath. | 2018 |