Objective

Laminar dielectric cable systems consist of high-pressure fluid-filled (HPFF), high-pressure gas-filled (HPGF), and self-contained fluid-filled (SCFF) system types. These cables in general have provided long-lasting service, surpassing their design life specifications. However, the advanced age of many of these assets might be a cause for concern. Replacement costs for laminar dielectric cable systems are high and the consequences of electrical failures or fluid leaks are significant. Research is needed to:

- Improve understanding of laminar dielectric cable system failure mechanisms.

- Develop and demonstrate inspection, diagnostic, monitoring, and remediation techniques.

- Provide guidance and develop strategies for effective operation, maintenance, life extension, and replacement.

Underground transmission engineers, designers, and managers may use the knowledge base, guidelines, methods, and technologies developed in this project to improve productivity, lower cost of operation and maintenance, and extend the life of laminar dielectric cable systems. Reliability and safety can be enhanced, and asset management strategies can be improved. Maintenance personnel can make more effective use of staff time and budget resources by applying new inspection methods and monitoring technologies. Planners may learn where to apply selective upgrades and retrofits through a better understanding of the relative conditions of their asset fleet, as well as where and under what circumstances cable systems are most susceptible to damage. In addition, utilities can apply the knowledge of corrosion mechanisms and detection to fine-tune the monitoring of their systems to enhance public and environmental safety.

Research Value

This research produces new understanding, methods, and tools that could improve the ability of engineers and planners to assess the condition of laminar dielectric cable systems and take proactive steps in operating and maintaining these systems to extend asset life and prevent unexpected outages. Benefits of this project may include:

- Better understanding of failure mechanisms and prevention procedures for longer asset life, fewer customer outages, and lower operations costs.

- Effective inspection and monitoring of assets, leading to increased asset utilization, rapid maintenance intervention prior to spontaneous failure, higher reliability, and lower repair costs.

- New inspection techniques and tools to increase staff productivity and reduce overall maintenance costs.

Planned 2025 Research

This project investigates and develops condition assessment methods and procedures for laminar dielectric cable systems. Efforts focus on life extension, improved reliability, reduced operation and maintenance costs, and improved support for asset management decision-making protocols. EPRI intends to direct its research at one or more of the following areas:

Evaluate and demonstrate advanced diagnostic techniques to assess conditions of laminar dielectric cables.

Develop best practices in dissolved gas analysis and insulating paper and fluid testing for effective deployment of the technologies.

Develop vintage information for laminar dielectric cable systems for improving asset management strategies.

Conduct investigations to better understand failure mechanisms of laminar dielectric cables.

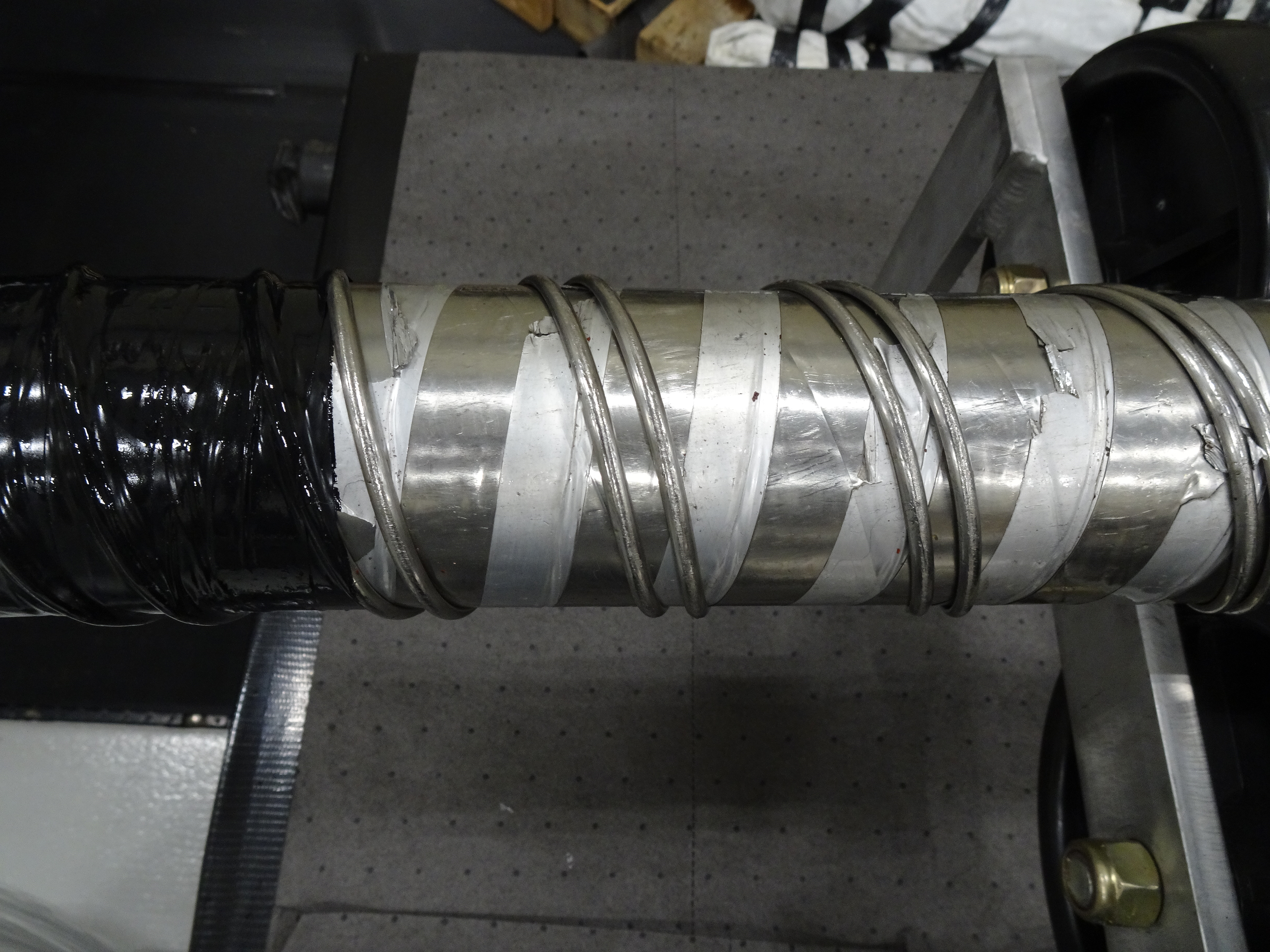

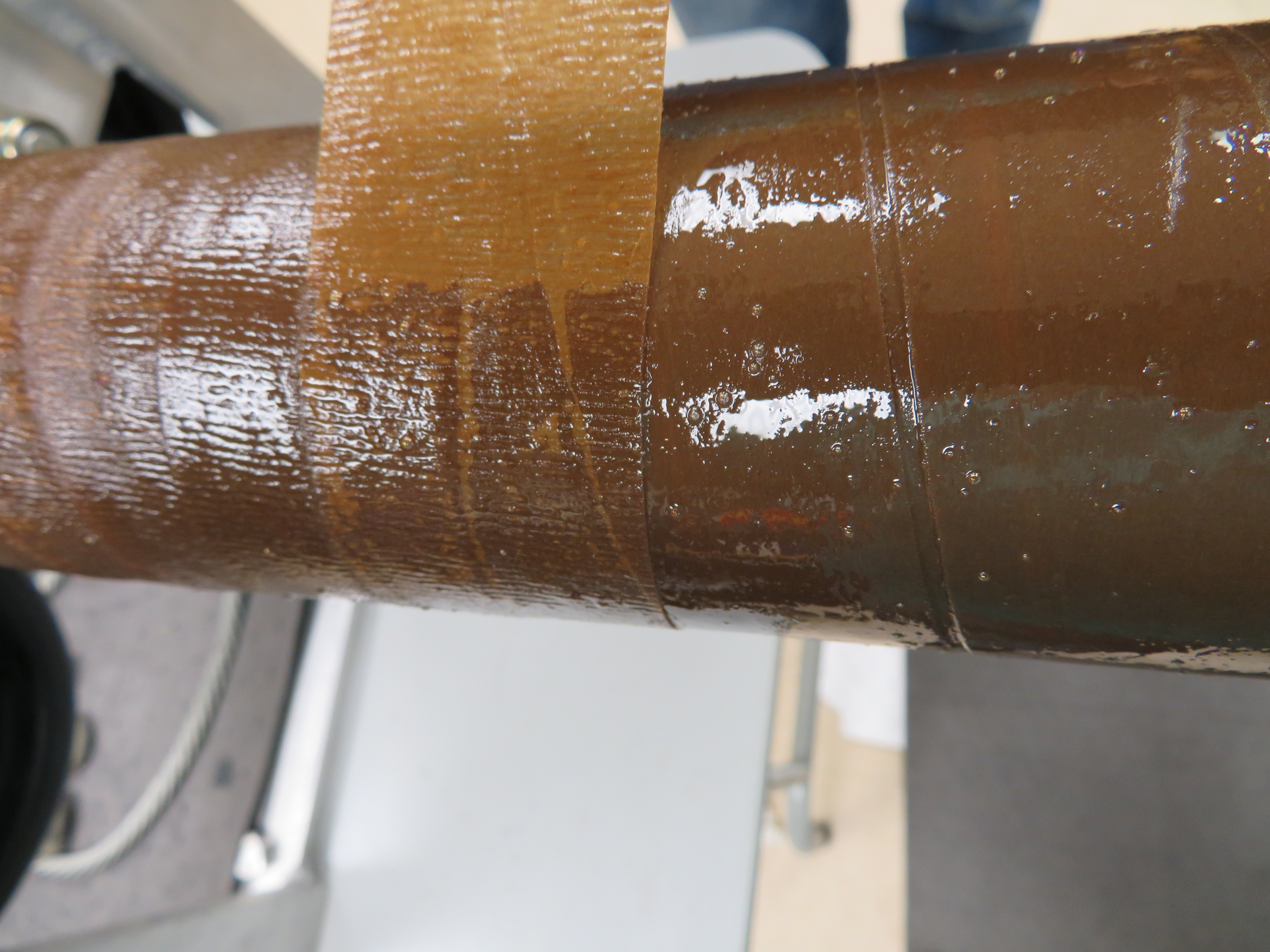

Study buried steel pipe coating degradation as a function of coating types, coating ages, pipe installation environments, coating application methods, and stray current conditions.

Evaluate and develop methods to effectively detect and mitigate corrosion and corrosive environments.

Develop technical bases for best practices to improve the effectiveness of cathodic protection systems.

Anticipated Deliverables

| Deliverable | Description | Date |

|---|---|---|

| Inspection, Assessment, and Mitigation of Buried Steel Pipe Corrosion (reports) | The task applies various detection techniques to investigate their effectiveness, while studying coating degradation as a function of coating types, pipe installation environments, and stray current conditions. | December 2025 |

| New Technique Development for Online and Off-Line Condition Assessment of Laminar Dielectric Cable Systems (report) | This task will evaluate and characterize new techniques for condition assessment and diagnostics of laminar dielectric cables, with emphasis on techniques that provide localization information on potential defects or degradation and continuous online monitoring. Techniques under investigation include prototype testing of test stations for buried steel pipe corrosion monitoring. | December 2025 |

| EPRI Guide for Testing Insulating Paper and Fluid of Laminar Dielectric Transmission Cables (report) | This task is a multi-year effort to create an up-to-date guide to test and analyze insulating paper and fluid of laminar dielectric cable systems to assess insulation and system conditions. This report includes results from tests and case studies. | December 2025 |

| EPRI Dissolved Gas Analysis Guide for High-Voltage Cables and Transformers—Case Studies (report) | This task continues prior EPRI research to create a comprehensive dissolved gas analysis guide to assess conditions of laminar dielectric cable systems. This report also includes example test results and case studies. | December 2025 |

| Evaluation and Documentation of Vintage Pipe-Type Cable Performance and Experience—2025 Update (report) | This task enhances the vintage guide to document changes in component materials, design, manufacturing, and other known issues of pipe-type cable systems. | December 2025 |

| Failure Root Cause Study of Laminar Dielectric Cables (report) | EPRI has performed comprehensive research in developing an approach for life management of cable systems, including cables, terminations, joints, pressurizing plants, and others. This task will continue such investigations and perform further laboratory experiments to better understand laminar dielectric cable aging and failure mechanisms. | December 2025 |

Past EPRI Research on Topic

| Product ID | Title | Description | Published Date |

|---|---|---|---|

| 3002027224 | Utility Experience of In-Pipe Thermo-Mechanical Bending (TMB) Events on Pipe-Type Cables | Results to determine performance of different cable constructions when subjected to TMB motion. | 2023 |

| 3002027220 | EPRI Guide for Testing Insulation Paper and Fluid of Transmission Laminar Dielectric Cable Systems | A consolidated industry guide for testing and data interpretation of fluid quality and paper tests performed on samples removed from aging in-service cable systems to inform and help make sound decisions on the condition and life of these assets. | 2023 |

| 3002027221 | Dissolved Gas Analysis Guide for High-Voltage Cables | A guide for DGA sampling, analysis, and data interpretation from laboratory and field experiences. | 2023 |

| 3002027223 | EPRI Evaluation and Documentation of Vintage Pipe-Type Cable Performance Experience | A guide for cable users to record major and subtle changes in design, materials, manufacturing, and recorded issues of key components of pipe-type cable systems. | 2023 |

| 3002027217 | Mitigation, Inspection, and Monitoring of Corrosion on Buried Steel Pipes of Pipe-Type Cable Transmission Systems | Report on corrosion fundamentals, mitigation options, stray currents, coating system performance, and various inspection and assessment techniques of pipe-type cable buried steel pipes. | 2023 |

| 3002027219 | EPRI Buried Pipe Test Station Development for Condition Monitoring of Buried Steel Pipes in Pipe-Type Cable Systems | Report on development of a buried pipe test station for use in condition assessment of buried steel pipes in pipe-type cable systems. | 2023 |

| 3002024547 | Best Practices for High-Pressure Fluid-Filled (HPFF) Pipe-Type Cable Pressurization Plant Upgrades | Overview of operating principles for HPFF pipe-type cable pumping plants and a description of factors to consider when evaluating pumping plants for upgrades or replacements. | 2022 |

| 3002021328 | Evaluation of Three Laminated Paper Polypropylene (LPP) Cable Pieces with One Containing Failure | Results of an analysis of a 345-kV failed LPP cable. A series of radial electrical, physical, and chemical tests were conducted on dissected cable pieces. Exchange of pipe and impregnation fluids were investigated. Analysis determines the condition and life of the cable. | 2021 |

| 3002019131 | Determining Root Causes of Pipe-Type Cable Failures—Impact of Fluid Freezes on Energized High-Pressure Fluid-Filled Pipe-Type Cable Insulation | Report on results of investigations on impact of low temperature on paper/oil dielectric insulation of pipe-type cables and temperature limits to ensure energized cable insulation performance. | 2020 |