Objective

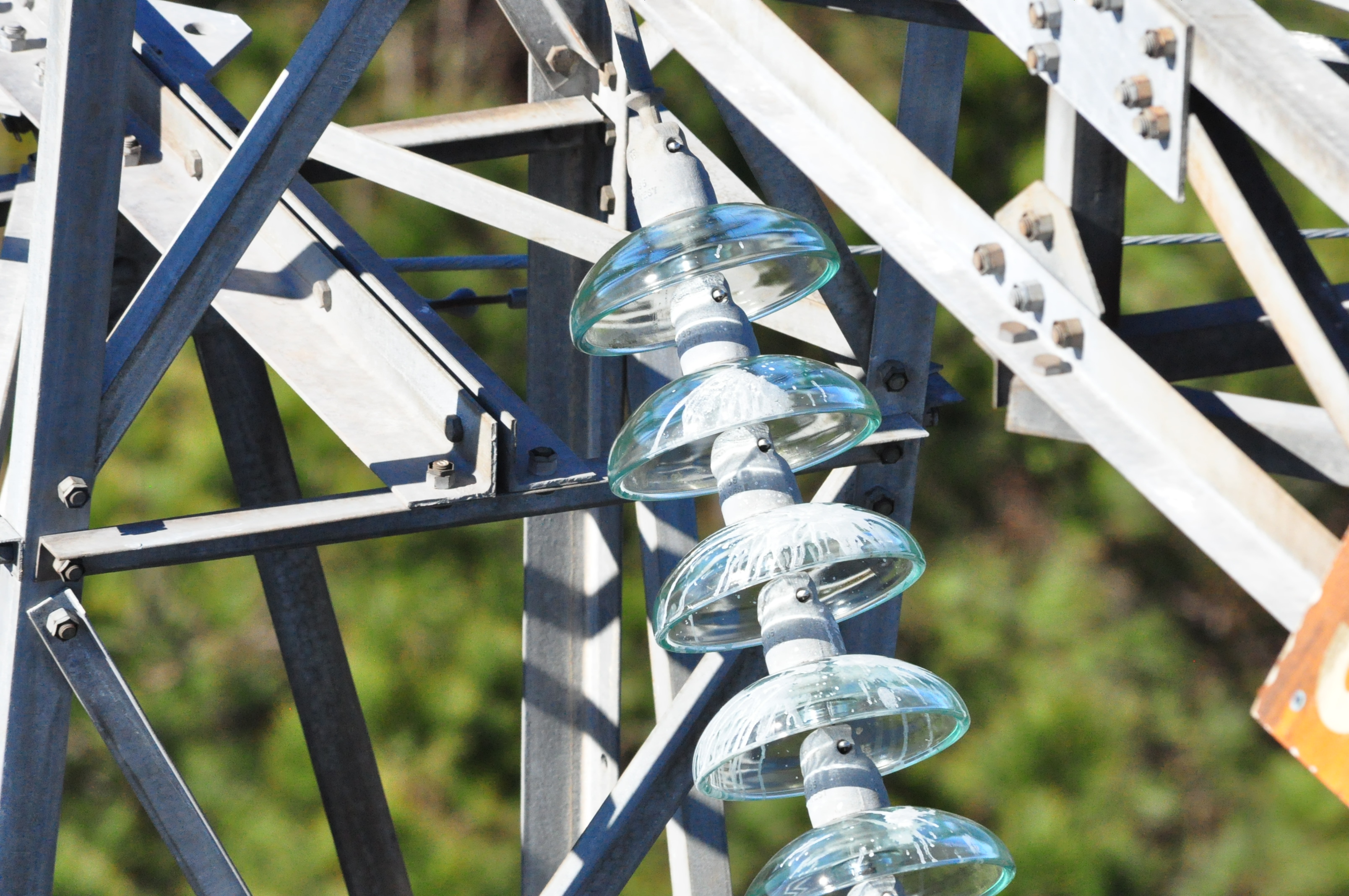

As populations of porcelain and glass insulators approach or exceed their expected service life, utilities are seeking end-of-life metrics to prioritize maintenance and replacement programs. To achieve this, utilities need information on insulator performance (both new and in-service), strategies for determining replacements, and effective tools and technologies for inspection and assessment. As utilities replace aging insulators, developments in glass insulator designs and changes in porcelain insulator manufacturing necessitate new training on the selection, application, and inspection of these insulators.

Concerns have also been raised about the performance of new insulators from both traditional and non-traditional vendors. Additionally, many utilities that have not previously used glass insulators are now considering this technology. Recently, manufacturers have introduced factory-applied room-temperature vulcanized (RTV) silicone rubber coatings on glass insulators to enhance their contamination performance. However, there is limited information on the long-term performance of these coatings and their impact on inspection, assessment, and maintenance.

This project’s objectives are aimed to address the technical challenges associated with aging insulator populations and shifts in design and manufacturing by performing tasks to:

- Assess new and novel designs (including rubber coatings) under representative in-service conditions

- Assess the overall condition of aging insulator populations

- Effective knowledge transfer

Research Value

This project can provide the following benefits:

- Assist in the selection, inspection, and maintenance of glass and porcelain insulators

- Offer information on insulator technologies, enabling lower-cost and/or improved technical solutions

- Enhance understanding of performance issues for existing and new insulators in contaminated environments, and provide strategies to address these issues

- Evaluate and identify high-risk porcelain/glass insulators or populations of insulators before failure, helping to maintain a reliable electricity supply to the public

Approach

In 2026, this project aims to enhance the industry’s knowledge of porcelain and glass insulators through the following initiatives:

Develop Porcelain and Glass Insulator Vintage Guide: Given the industry’s extensive history with porcelain insulators, assessing and managing these aging populations will be necessary for many years. However, test data alone are not sufficient for end-of-life decisions. With the increasing use of glass insulators, this task will develop a guide that consolidates essential information to help utilities assess failure risk and determine when to replace insulator populations based on their make and vintage.

Evaluate the Performance of RTV-Coated Insulators: Manufactured RTV-coated glass insulators are relatively new and have limited global experience. This task aims to evaluate the performance of RTV coatings in various service environments and assess if tasks such as cleaning can be used without damaging the coating.

Study Glass Insulator Failure: As glass insulators become more common, reports of shattering may increase. Tools to understand the causes of shattering can expedite issue resolution. EPRI intends to build on existing data to develop methods for determining the causes of glass insulator failures.

Evaluate Steep Impulse Flashover Test Methodology: There is some indication that glass quality may be assessed with steep impulse flashovers. EPRI intends to test utility samples of new glass insulators to understand how impulse testing can be used for this assessment.

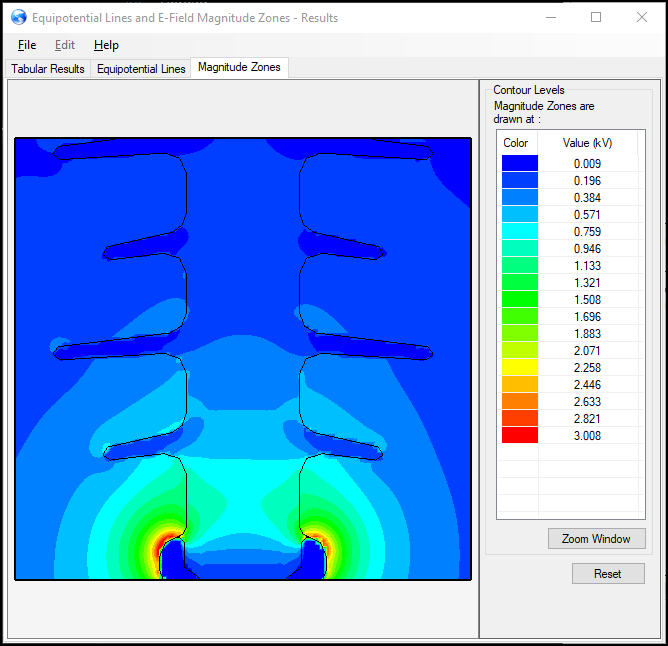

Update the Insulator Calculation Engine (ICE): With the emergence of RTV silicone-coated glass insulators, controlling corona to reduce RTV degradation becomes crucial. This tool helps calculate electric field stress along an insulator string to determine the need for grading devices. EPRI continually updates this tool based on user feedback to ensure ease of use and relevance.

Insulator Reference Book (The Violet Book): This comprehensive guide provides state-of-the-art information on insulator selection, inspection, and maintenance. Revisions to the book aim to include the numerous mechanical considerations when selecting insulators for different configurations.

Provide Tools and Resources on The transmission Resource Center: The following calculators, tools, result summaries, and references are planned to be available on the Glass and Porcelain Insulator Transmission Resource Center:

| Resource Title | Resource Type |

|---|---|

| Mechanical Failing Tensile Load Assessment | Calculator |

| A Study of Silicone Rubber Coated Glass Insulators: Comparing the Performance of Fully Coated and Bottom Coated Insulators | Result Summary |

| Lessons Learned from Porcelain Insulator Failures | Result Summary |

| A Study of How Glass Insulators Break | Result Summary |

| Insulator Reference Book (TheViolet Book) | Reference |

| Overview and Terminology of Porcelain and GlassInsulators | Reference |

| Key Processes of Contamination Flashover Process | Reference |

| The Combined Mechanical and Electrical (M&E)Strength Test | Reference |

Anticipated Deliverables

| Deliverable | Type |

|---|---|

| Insulator Reference Book (TheViolet Book) | Reference Book |

| Insulator E-field Modeling Software(Insulator Calculation Engine [ICE]) | Software |

| Porcelain and Glass Insulator Vintage Guide | Technical Update |

| Contamination | Technical Update |

Past EPRI Work on Topic

| Product ID | Title | Description | Published Date |

|---|---|---|---|

| 3002029600 | Development of Methods to Assess the Contamination of Insulators with Rubber Coatings | This report outlines various testing methods, including fog chamber tests and the Apparent Salt Deposit Density(ASDD) test, highlighting the complexities involved in accurately assessing contamination levels on coated insulators. | 2024 |

| 3002027069 | A Study of Aging Porcelain Insulator Performance | This report presents test data showing how the age of insulators affect their strength performance. | 2023 |

| 3002024448 | Results of Salt-fog TestingInsulators with RTV coatings | Describes the process to perform salt fog flashover testing of glass insulators with RTV coatings. | 2022 |

| 3002021554 | Summary of Lessons Learned on Failure Analysis of Porcelain Insulators | Summarizes the forensic analysis of several porcelain insulator failures and the lessons learned. | 2021 |