Calculators

Minimum Approach Distance Calculator (Web-based) This calculator assists in estimating the Minimum Approach Distance (MAD) for working on transmission lines with voltages above 72.5kV phase-to-ground, based on IEEE and IEC methods.

Research Results Summaries

Live Working Rope – Compilation of Electrical Testing Results

EPRI has conducted electrical and mechanical tests on live working ropes from various manufacturers and designs, examining them under various conditions to gain a better understanding of their degradation process. This research aims to establish a safe threshold for determining when these ropes should be taken out of service.

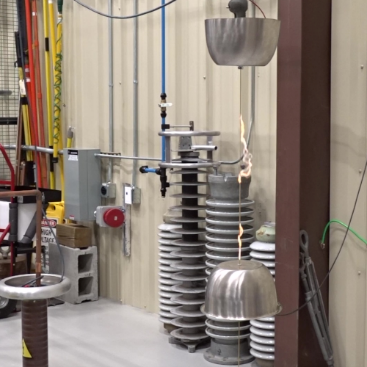

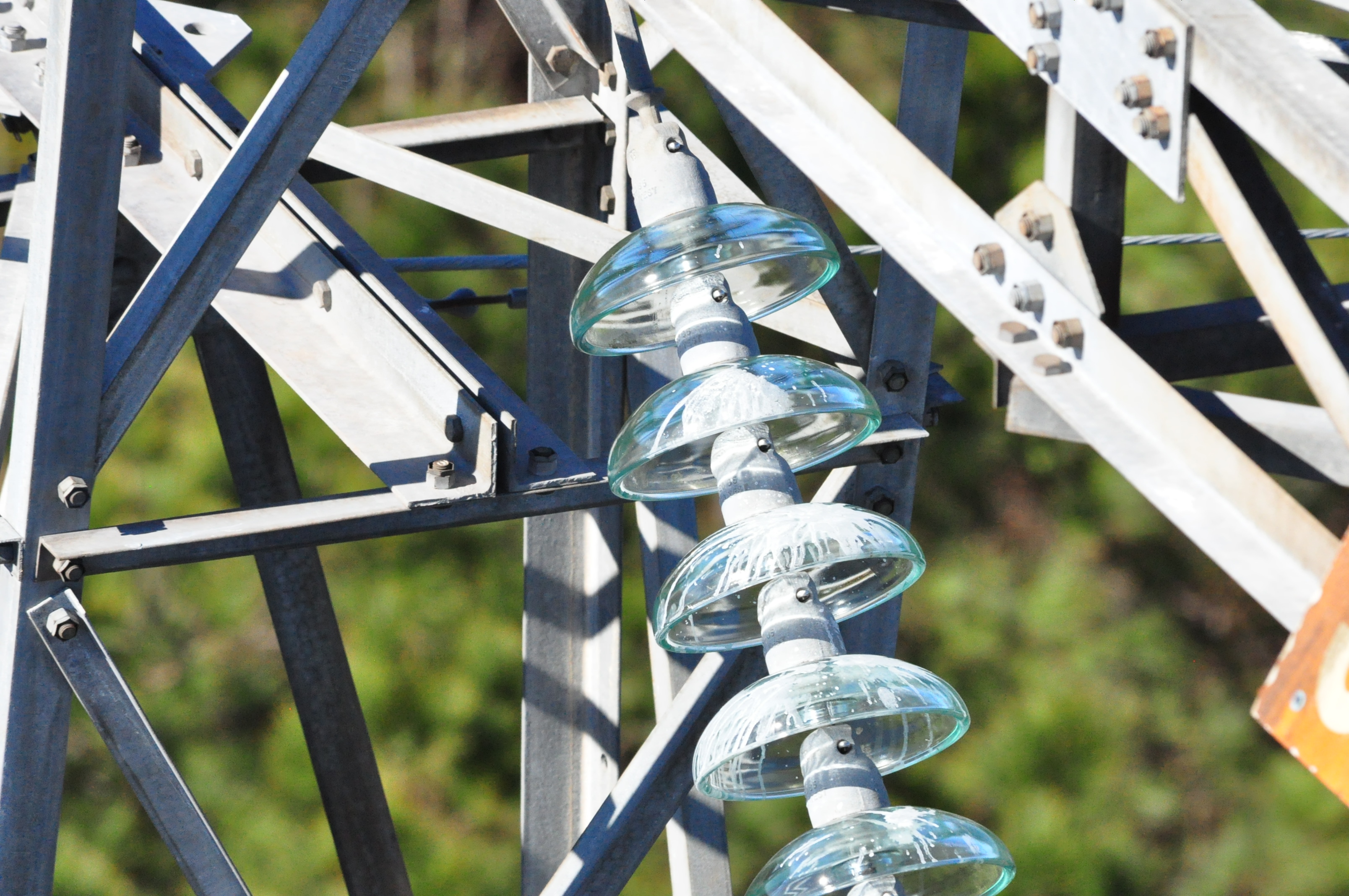

Live Working Rope Testing and Specification

Specially designed insulating ropes are used in Live Work along with rigid insulating tools such as hot sticks. Currently available insulating ropes are critical for the safety of workers and the installation, and have several advantages and disadvantages over rigid tools, as well as promote the leverage of the live working barehanding technic. Results from testing.

ESRI Survey123 Tracking Form Testing and Field Inspection Form for Insulating Tools

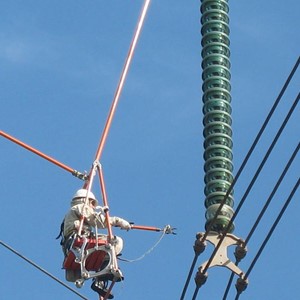

EPRI has been actively involved in the care and maintenance of hot sticks and dielectric ropes used in service. Over the past 20 years, several unexplained flashover incidents involving insulating tools have occurred across North America. As a result, many utilities have temporarily halted live line work until these events are scientifically understood. This highlights the need for thorough technical investigations, which EPRI and other stakeholders are currently conducting.

Reference Information

Selected Standards and Regulations

This chapter lists selected standards and regulations related to live work in alphabetical order by the name of the organization that developed the standard or regulation, and in numerical order within each organization. Descriptions of most listed documents are taken from the respective websites.

Minimum Approach Distance – Compilation of Calculation Procedures and Training Videos

The Minimum Approach Distance (MAD) is the closest distance a qualified electrical worker is permitted to approach either an energized or a grounded object, as applicable for the work method being used.