Objective

Polymer and composite insulators offer a lightweight and improved contamination performance alternative to porcelain and glass insulators. Although many of the early design challenges have been addressed by manufacturers, utilities still need to understand how to select, apply, and inspect these components to achieve the expected design life. Understanding their long-term performance, developing design guidance, and enhancing acceptance criteria can help utilities gain knowledge to confidently specify and apply polymer insulators. Utilities can create designs and select components capable of meeting long-term performance objectives.

This project addresses the specification, application, inspection, and in-service performance of polymer insulators through long-term and short-term research tasks, such as:

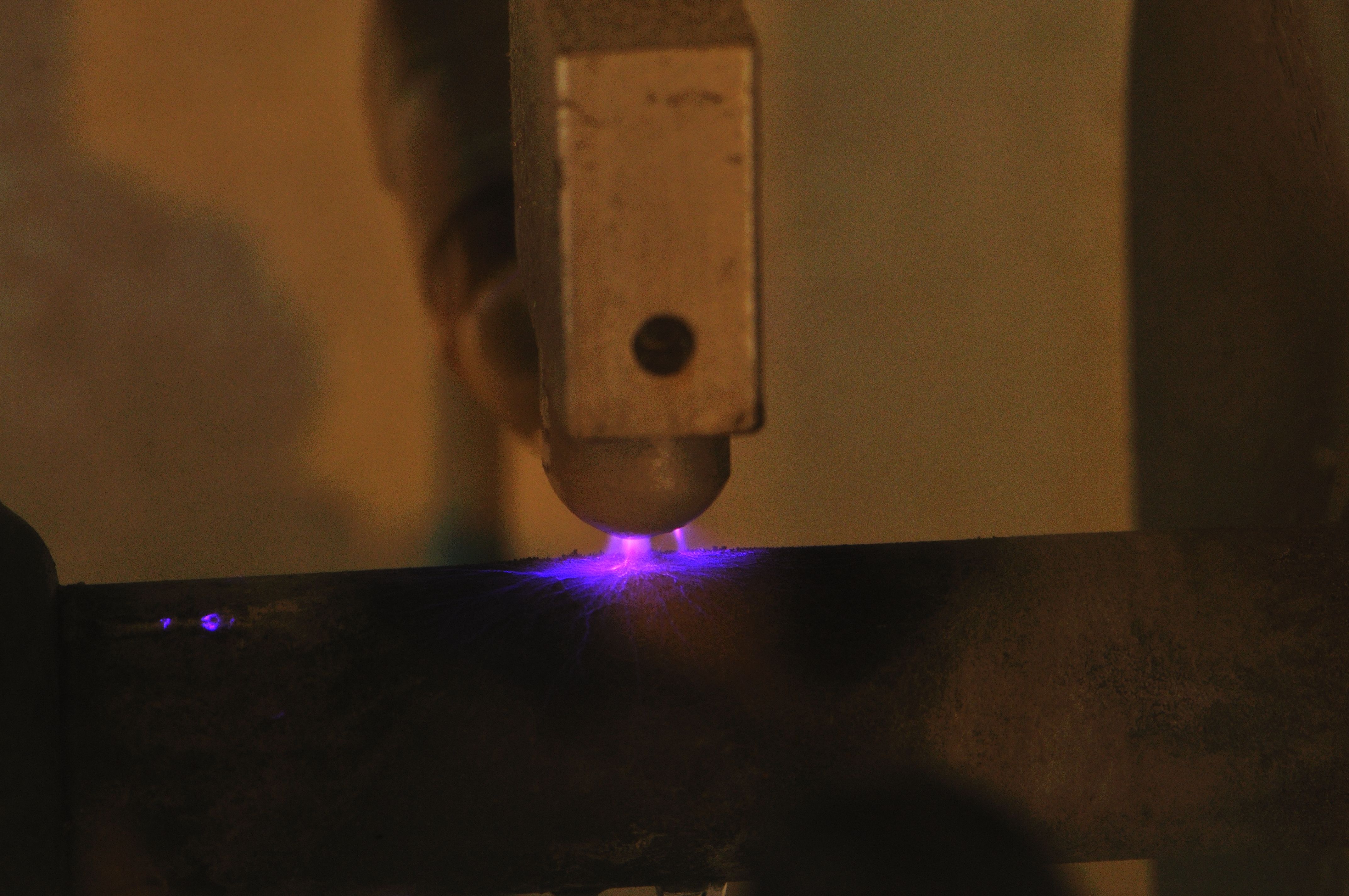

- Performing testing in full-scale and small-scale aging chambers to help identify aging and degradation mechanisms

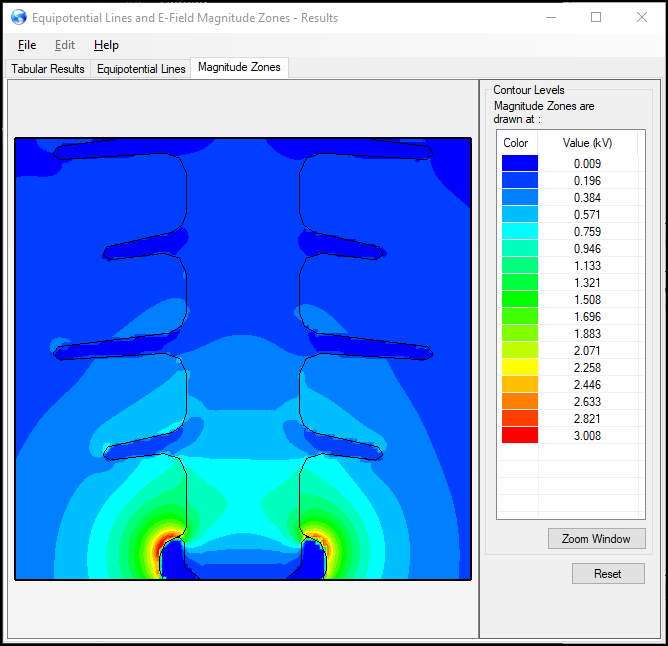

- Developing software tools for determining electrical stress levels

- Develop short-term tests to assess insulator performance, particularly for new designs or manufacturers on the market

- Conducting workshops and issuing reference books so utilities can stay up to date on insulator developments and test methods

Research Value

The project can have the following benefits:

- Provide technical information for developing more effective specifications and improving the long-term performance of composite components

- Reduce construction costs and improve performance through correct handling and applying of composite components

- Extend polymer insulator life to reduce the occurrence of sustained outages, which helps maintain a reliable electricity supply to the public

- Improve technical knowledge and productivity by providing better information and tools

Planned 2025 Research

This project addresses a range of polymer insulator concerns through short-term and long-term research tasks and develops various technical knowledge transfer tools that help utilities with selecting, applying, and inspecting polymer insulators. Activities include:

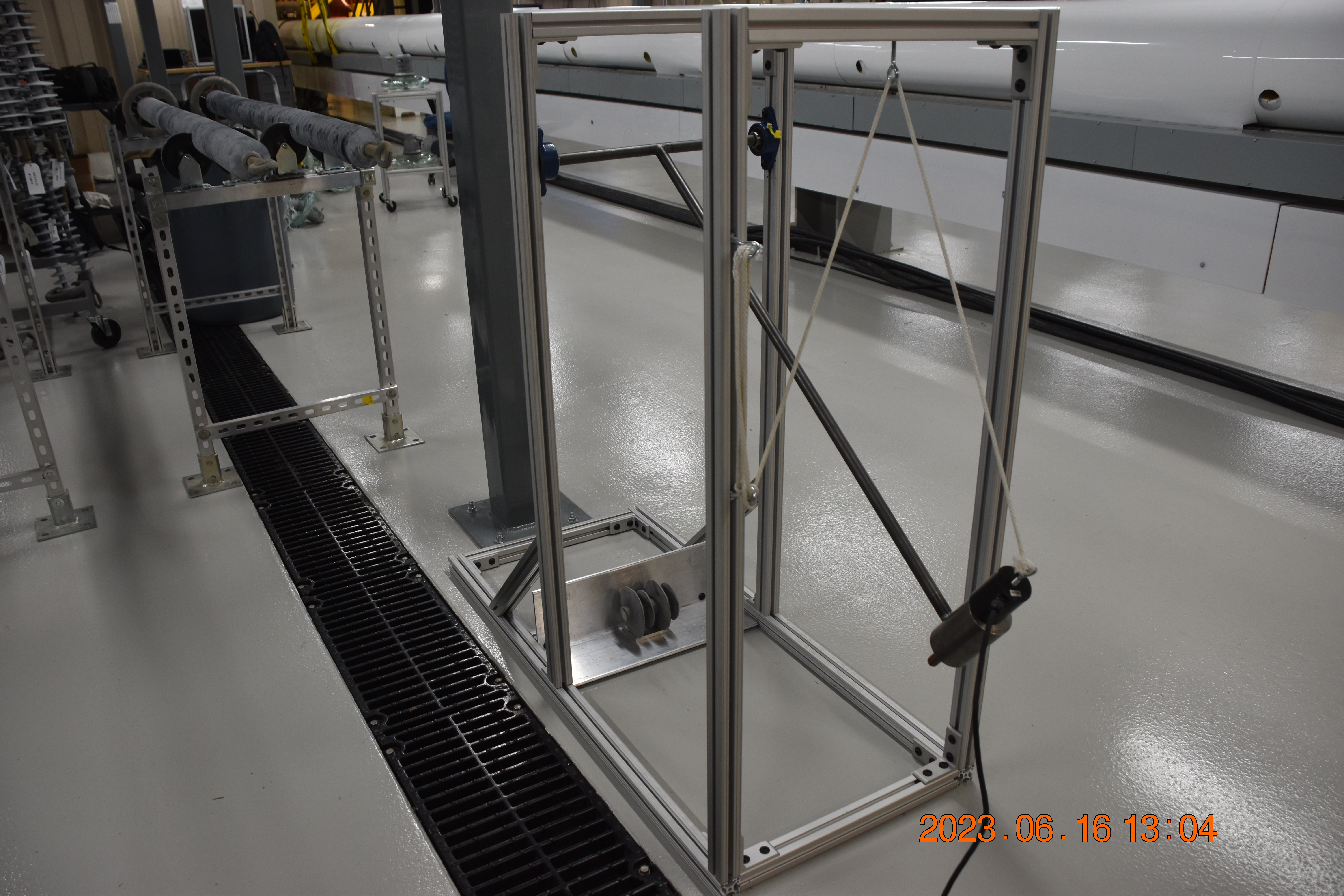

Multi-Stress Aging Tests: For more than two decades, EPRI’s multi-stress aging chamber has provided utilities with timely information about the performance of polymer insulators in less time than from in-service experience alone. As such, the chamber continues to be an asset to utility members. As some components are removed for evaluation, EPRI intends to add designs into the available space to represent the industry direction.

Small-Scale Degradation Tests: EPRI has developed several small-scale degradation tests that have proven repeatable, reproducible, and relevant to assessing an insulator’s performance to specific in-service degradation. EPRI has continued expanding the number of small-scale tests focused on different in-service issues. As new materials are developed, these tests are performed to provide members with performance guidance. EPRI continues to refine the test methods and tools as data are collected and technology becomes more advanced.

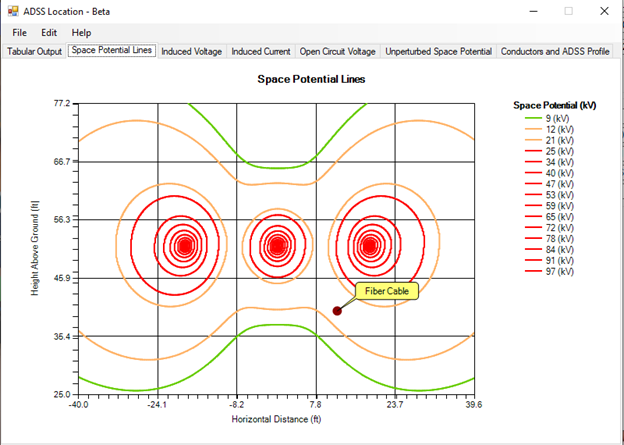

E-Field Modeling Software: Because electric fields are a critical factor in the service life of polymer insulators, this software helps calculate the electric field on new or existing insulator designs so utilities can determine the need for corona rings. EPRI continually works with user feedback to keep this tool relevant and easy to use.

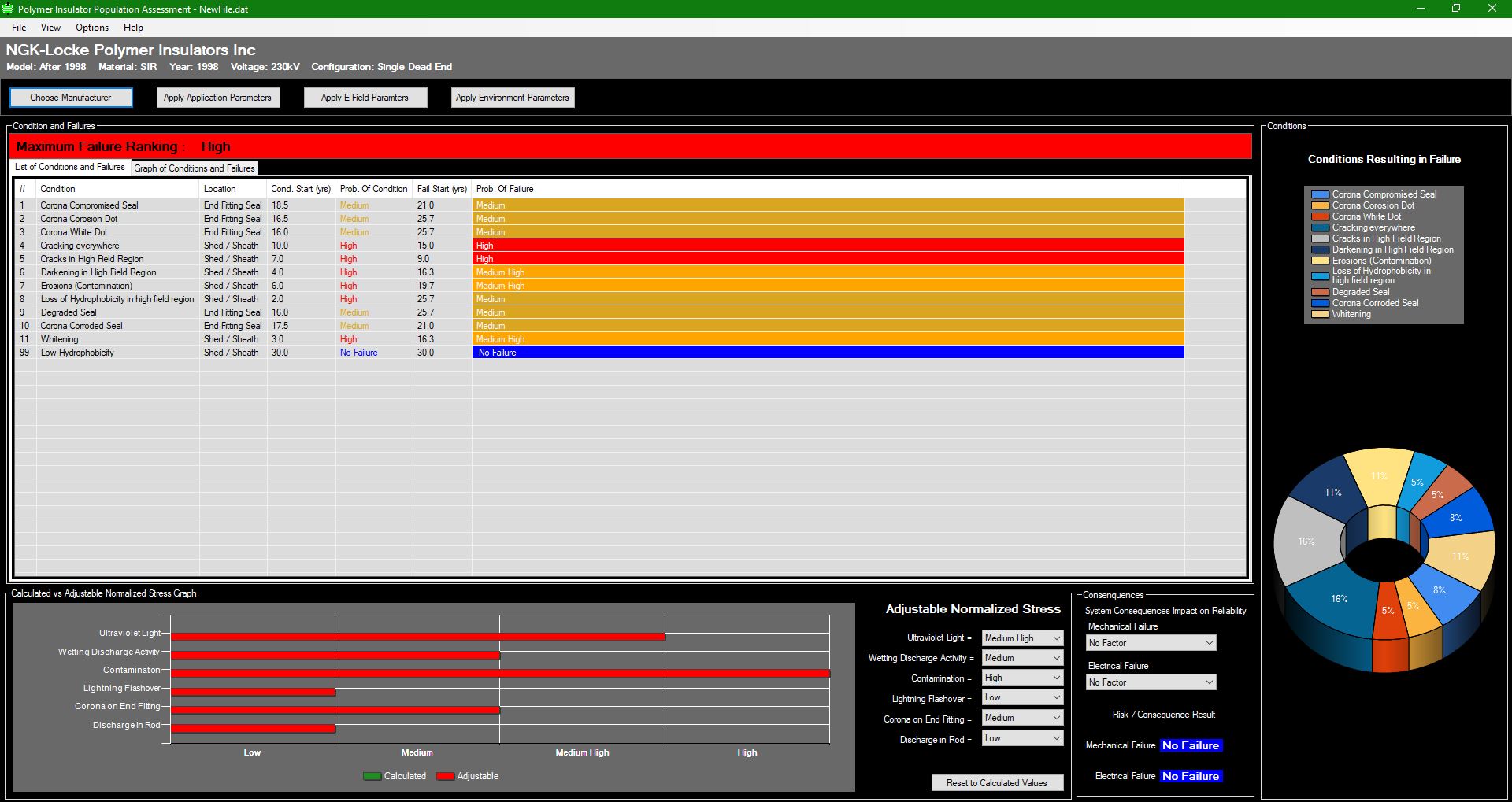

Polymer Insulator Population Assessment (PIPA): This population assessment web-based software determines the potential condition and failure risk of in-service populations of insulators. Members can use this tool to quickly understand which population of insulators is prone to degradation. EPRI continues to work on improving accessibility for the user and refining the algorithms based on new data.

Insulator Reference Book: This book is a comprehensive reference guide that provides state-of-the-art information on insulator selection, inspection, and maintenance. There has been new development in contamination research that can enhance the existing information in the book.

ADSS Application: A web-based software tool to help users understand the electric field influence of high-voltage transmission lines on all-dielectric self-supporting (ADSS) installations. EPRI continues to work on improving accessibility for the user.

Handling Tests: These tests are being developed as a supplement to performance tests. They are intended to identify polymer insulators that, in addition to meeting in-service performance needs, resist handling damage. EPRI intends to develop a test protocol based on the several years of test development.

Nondestructive Weathershed Bonding Assessment: This task intends to evaluate a combination of ultrasound technology and nondestructive stress application to reveal poor weathershed bonding in polymer insulators. EPRI intends to expand the data set across multiple makes and designs to verify the test method.