Calculators

Mechanical Failing Tensile Load Assessment

To help a utility determine if a population is at risk of incurring insulator failures, a statistical approach is used.This tool lets the user explore how the test data affects the statistical population assessment of insulators.

Research Result Summaries

A Study of Silicone Rubber Coated Glass Insulators: Comparing the Performance of Fully Coated and Bottom Coated Insulators

EPRI performed salt fog testing on glass insulator that were fully coated with silicone rubber and bottom coated only to learn how they performed. This knowledge can help utilities be better informed about the options being presented to them.

Lessons Learned from Porcelain Insulator Failures

EPRI performs failure assessment of insulators regularly. This report describes the trends identified from tracking failures and some lessons learned from detailed studies.

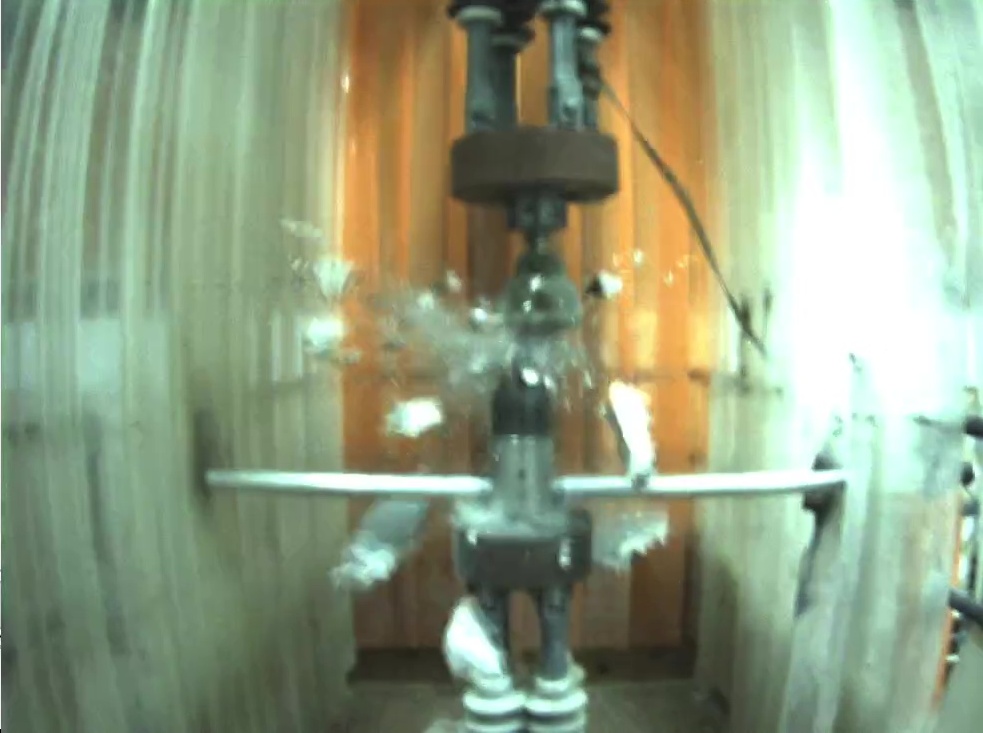

A Study of How Glass Insulators Break

EPRI performs failure assessment of insulators regularly. This report describes the trends identified from tracking failures and some lessons learned from detailed studies.

Reference Information

Overview and Terminology of Porcelain and Glass Insulators

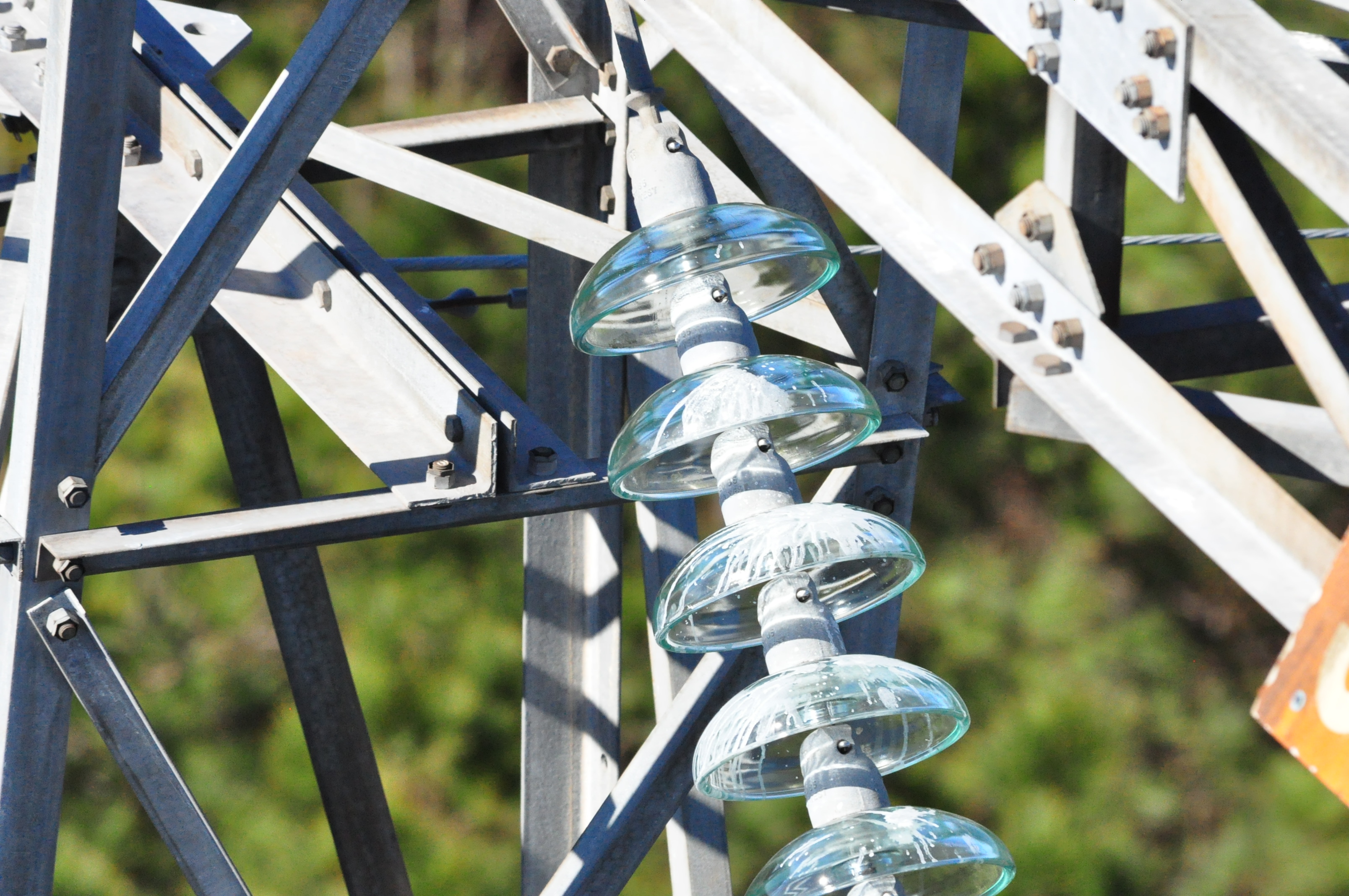

A suspension insulator, which is sometimes referred to as a “disk insulator” or “bell” is defined by ANSI C29.1 as an insulator with attached metal parts having means for non-rigidly supporting electric conductors. In the IEC standards this insulator type is identified as “cap and pin insulator”, but this term in conflict with ANSI C29.1 in which “cap and pin” identifies a different kind of insulator.

Key Processes of the Contamination Flashover Process

This table shows the 8 step process leading to contamination flashover.

The Combined Mechanical and Electrical (M&E) Strength Test

Although the term M&E test has been around for several decades, only a small percentage of utility personnel have the opportunity to witness a test and consequently, many are unaware of exactly how such a test is performed. This article describes what the M&E test is and how EPRI perfoms the test.

Videos

Insulator Population Assessment

Insulator populations are approaching end of design life for many utilities but pressures to maximize the life of components has them basing replacement on condition rather than time. This video describes one of the test ares in EPRI’s lab for assessing insulator conditions and collecting the mush needed information for utilities to make condition based decisions.