Research Result Summaries

Latest research results from the 138kV Research Substation The laboratory test protocols are currently being executed to expose on-line monitoring techniques rapidly and repeatedly to the types of faults likely to be seen by the monitoring devices once deployed in the field. The findings are expected to provide data sets that could form part of a utility’s decision-making process on monitor specification and interpretation

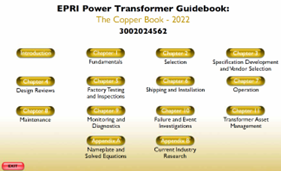

Copper Book Webinars Throughout the year 5 webinars are held on topics related to the Copper book. This link takes you to the videos for past sessions you may have missed.

Reference Information

Supplemental Opportunity: On-line monitor deployments in the EPRI 138kV Research Substation

Under this 37-101 related supplemental project, members can accelerate the deployment of on-line for evaluation in the EPRI 138kV research substation.

Key Research Question: Utilities are significantly expanding the substation deployment of on-line monitoring devices. There is an expanding range of existing and emerging technologies to meet this need. The important research question asks how the various technology options for on-line monitoring devices would perform under a wide range of system, environmental and equipment health conditions.

Objective: The objective of this project is to answer the key research question through carefully designed test protocols in a laboratory environment. The laboratory test protocols will be executed to expose on-line monitoring techniques rapidly and repeatedly to the types of faults likely to be seen by the monitoring devices once deployed in the field. The findings are expected to provide data sets that could form part of a utility’s decision-making process on monitor specification and interpretation.

- A systematic approach where well-defined test protocols are applied.

- An increased understanding of the application of sensor data and the benefits that can be derived.

Approach: The research approach is to use EPRI’s 138kV Research Substation to deploy the selected on-line monitoring technologies and then apply to each monitor the repeatable test plan developed for each technology. In addition, the research test plan thoroughly documents the maintenance costs over the full test period, allowing for insights into the cost of ownership. In this latest review period, two new monitors were deployed. In addition, for the full suite of monitors data was continued to be gathered every hour and defects were systematically added to the research substation to fully understand the monitor responses.

Videos

Technical Training on Transformers - Videos

As part of your participation in P37-101 you have access (both live and video after the fact) to the technical training webinars based on the copper book.

The link below leads you to the log-in page and once signed in, will lead you to the page below where you can see the trainings listed. Searchers can click on the training session they are interested in or use the search bar to type in a particular title.