Project Overview

Objective

With ever-increasing pressures on the supply chain, utilities are becoming more interested in alternative materials to construct transmission lines. The objectives of this research are to increase the knowledge base of members on the use of alternative materials of transmission structures with specific focus on mechanical and electrical performance as well as economic considerations.

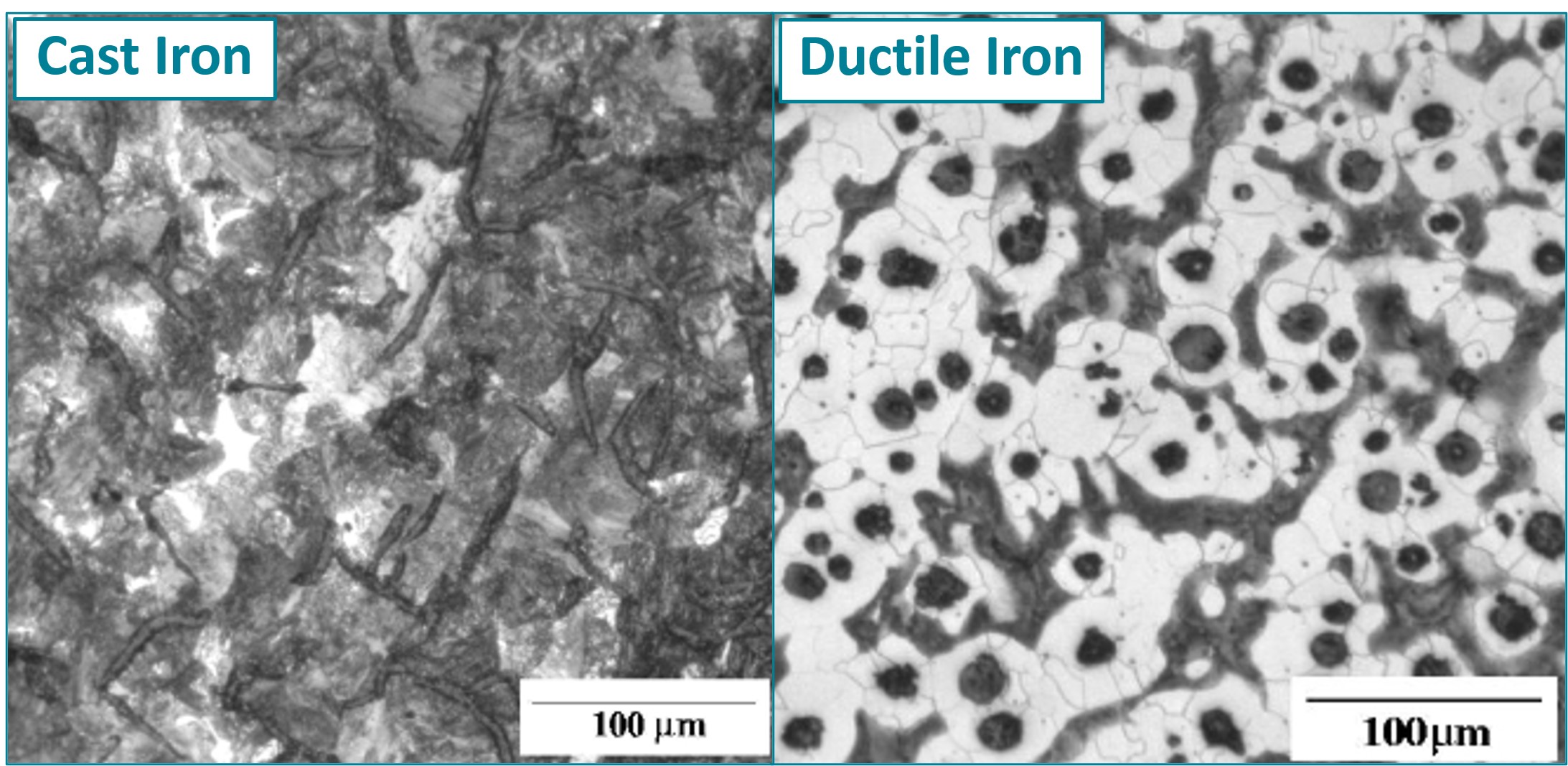

Two leading alternative materials in this space include ductile iron and composite materials. EPRI’s research aims to improve utility expertise in the design, application, performance characteristics, degradation modes, and future maintenance requirements of these non-traditional materials. Knowledge is generated through collaboration with utility members, structure manufacturers, and, most importantly, through laboratory testing completed at EPRI facilities.

Research Value

Research on ductile iron and composite structures will:

- Increase reliability and safety through the application of high-reliability structure materials

- Lower lifecycle costs and increase system reliability by leveraging the advantages of ductile iron and composite structures

- Enable utilities to utilize alternative materials to free up supply chain constraints by improving confidence when applying ductile iron or composite technology

- Increase understanding of performance characteristics and degradation modes of ductile iron and composite materials

Approach

EPRI intends to perform the following tasks in 2026:

Develop Guidance on Accounting for Fiber-Reinforced Polymer (FRP) Degradation: Over the last several years, EPRI has been producing an application guide for composite structures built upon research performed in this project. The guide covers topics such as composite pole and crossarm manufacturing, degradation modes, installation, maintenance, and more. In 2026, EPRI intends to update the Composite Structures Application Guide focusing on the degradation of FRP composite materials. An emphasis will be placed on how engineers can account for material degradation to ensure reliable performance.

Develop Guidance from Ductile Iron Strength Testing: EPRI is undergoing a multi-year effort to develop the Ductile Iron Structures Application Guide for utility engineers. In 2026, EPRI intends to update this guide focusing on the findings from full-scale pole breaks as well as a detailed overview of the ductile iron manufacturing process.

Test Effects of Composite Material Outdoor Exposure: In 2026, EPRI plans to kick off a multi-year effort to understand the real-world aging of FRP composite materials subject to ultraviolet radiation and moisture. EPRI has done extensive research on FRP aging in an accelerated laboratory environment, but correlations to outdoor exposure durations remain difficult. This initiative seeks to close the gap between real-world and accelerated aging of FRP materials, providing insights to transmission engineers on expected lifespans of FRP composite poles. Photo courtesy of Q-Lab.

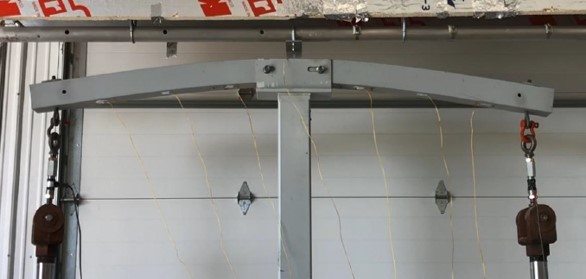

Perform Mechanical Tests on Accelerated Aged Composite Crossarms: For the last three years, EPRI has been engaged in accelerated aging of FRP composite crossarms at its laboratory in Lenox, Massachusetts. The target three-year aging cycle is set to finish in 2026. Upon completion, EPRI intends to subject the crossarms to full-scale mechanical testing.

Provide Cost Comparisons for Different Pole Types: This multi-year research effort is focused on helping engineers make the best decisions with regards to transmission pole material selection between wood, steel, concrete, fiber-reinforced polymer, and ductile iron. The Optimal Pole Material Selection Guide contains a qualitative review of each material type, representative structural designs, and pertinent design recommendations. In 2026, EPRI plans on updating the guide to include cost estimates for each material type to include procurement and installation expenses.

Provide Ductile Iron Transmission Structure Basics Training: While ductile iron poles are becoming more common in the transmission industry, many utilities are unaware, or lack the knowledge base for implementation. This training course, in partenrship with EPRI U4T, will cover the basics of ductile iron transmission structures. Course topics may include material fundamentals, manufacturing, design process, and installation recommendations.

ProvideTools and Resources on the Transmission Resource Center: The following calculators, tools, result summaries, and references are planned to be available on the Ductile Iron & Composite Structures Transmission Resource Center

| Resource Title | Resource Type |

|---|---|

| Evaluation of Wildfire Protection Methods for Composite Utility Structure Materials | Result Summary |

| Effects of Environmental Aging on Composite Poles | Result Summary |

| Recommendations for Grounding of Composite Utility Poles | Result Summary |

| Loading Composite Utility Poles to Failure to Understand Failure Modes | Testing Video |