Research & Technical Content

Calculators

Polymer Insulator Population Assessment (PIPA) Application

The Polymer Insulator Population Assessment (PIPA) tool allows the user to evaluate the typical degradation, failure modes, and estimated lifespan of polymer insulators within specified environmental and application parameters. Users can use this tool to identify risks of failure and use that information to guide maintenance and replacement strategies.

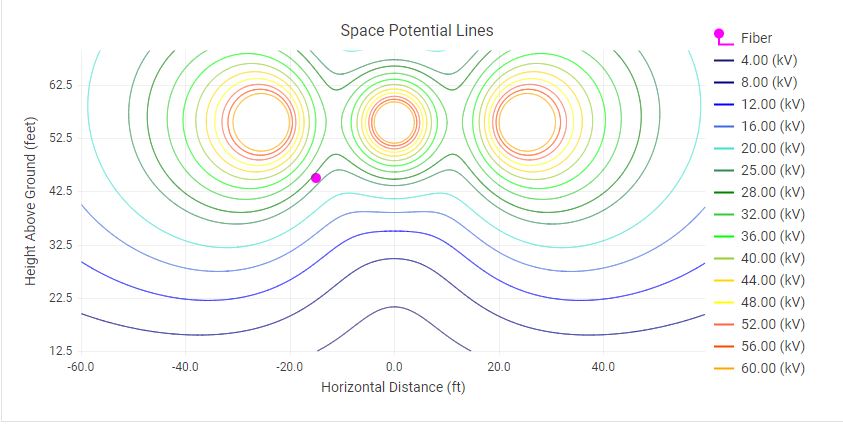

All Dielectric Self Supporting Application

This product is a software tool for assessing the stress on All Dielectric Self Supporting (ADSS) fiber cable installed on transmission structures. ADSS is a self-supporting cable made of fiberglass and Kevlar that spans up to 1,500 feet between structures in the proximity of energized conductors. The high voltage (HV) environment around ADSS stresses it with space potential, corona discharges, and contamination which together result in dry band arcing on the on the ADSS cable and damages the protective sheath. Utilities are tasked with locating ADSS cable on the structures so that the electrical stresses do not result in cable damage. This tool is developed to let users define the position of the phase wires and the ADSS cable and it will calculate the open circuit voltage, induced current, and space potential along the ADSS cable.

Benefits and Values

-

This software tool is designed to aid utility engineers is calculating the complex electrical stresses imposed on an ADSS fiber cable thereby guiding them to locate the cable where it will reduce the chance of degradation and failure

-

The software also lets the utility engineer investigate several locations prior to lab testing thereby reducing the number of lab tests required

-

Understanding the electrical stresses that lead to cable damage helps the utility select the best cable location and understand the cause of damage to existing installations

Research Result Summaries

Aging Chamber Report Tool (ACRT)

The 138kV / 230kV Accelerated Aging Chamber is a multi-year test of more than 50 polymer and fiberglass components. Photographic inspections occur twice a year. Thousands of photographs accumulate making conventional reports difficult to read. This reporting tool enables the reader to jump from component to component and inspection to inspection. The reader can easily compare components at different levels of aging. This tool will make reviewing the important results of this test easier for the reader allowing him/her to quickly adapt them to everyday operations.

Reference Information

Polymer Insulator Vintage Guide

As utility infrastructure ages, managers are faced with the challenge of identifying the installed equipment to make informed maintenance decisions. This tool presents to the user information about the make, model, and vintage of transmission line insulators. Specific details are included that help the user identify the equipment, understand how it was made, and know the issues that affect long-term performance. The tool includes numerous photos of examples.

Categorization of Hydrophobicity

A simple and practical approach to classify the hydrophobicity of insulators has been developed in 1992 by STRI in the “Hydrophobicity Classification Guide”.

Videos

Insulator Corona Cage Test Corona discharge activity can cause damage to polymer insulators that can lead to failure. While no corona is ideal, it may not be practical to consider all circumstances that result in corona activity. However, the design of the insulator end fitting may affect how corona interacts with the rubber and this video describes a test designed to investigate how much, if any, affect there is.