Project Overview

Objective

Electrical utilities depend on power transformers to be reliable and in good health. Since a transformer consists of multiple components, its ability to operate is determined by its weakest part. Bushings are integral to the operation of high-voltage transformers and are subjected to various stresses from the transformers and the environment. Industry surveys have indicated that over 20% of transformer failures can be attributed to issues with traditional electrical bushings. As a result, the electrical industry seeks alternatives or improvements to traditional oil-filled bushings.

Polymer bushings (also known as dry-type bushings) are a newer technology and offer several potential advantages compared to oil-impregnated paper bushings with porcelain exteriors. However, despite their benefits, there are still many unanswered questions regarding the longevity and reliability of dry-type bushings. This lack of information can lead to hesitation by utilities to adopt polymer bushings. With low adoption rates, the amount of field information available remains limited and grows slowly. This project aims to accelerate the amount of available information on polymer bushings and provide insights into polymer bushings for users and potential users through three primary functions:

- Provide a data-based, technical foundation for utilities to make decisions when specifying, operating, and maintaining polymer bushing technologies

- Offer best practices, as well as assessing and managing risks through early insights learned from laboratory testing and field experience

- Provide greater insight and understanding of the effectiveness of various diagnostic approaches used for oil-filled bushings when used with polymer bushings

One path to grow these areas is to have utilities and EPRI share their experiences with polymer bushings with one another, combined with new literature as it becomes available. Additionally, a greater understanding of polymer bushings can be made through the application of polymer bushings in simulated field conditions for long periods of testing (i.e., years) and by testing with climate extremes. Any new topics and/or concerns identified in such tests can then be studied with more targeted research.

In other words, the laboratory-based research is structured to probe specific uncertainties surrounding polymer bushings by performing a mix of long- and medium-term experiments. Meanwhile, short-term gains can be made through data collection from literature and users to extract insights. Questions the project seeks to probe include, but are not limited to:

- How do polymer bushings perform under extreme environmental conditions and operating stresses (electrical, thermal, and mechanical)?

- How would the polymer bushings be affected by overloading, and would different specifications and/or operating practices be required?

- Are present monitoring and diagnostic test methods sufficiently effective for assessing the condition of polymer bushings?

- Are there unique operating or maintenance concerns with polymer bushings?

- Can prevalent failure modes or emerging reliability issues be identified earlier to mitigate concerns with widespread adoption?

Research Value

The core values that this research aims to provide include:

- Enhancing confidence among users and potential users in adoption of polymer bushings

- Providing a robust technical basis for decisions when specifying, operating, and maintaining new polymer bushing technologies

- Reducing life-cycle risks and costs to improve reliability and affordability

- Assisting users in assessing and managing risks through early insights gleaned from laboratory testing and field experience

- Presenting findings that provide a better understanding of the efficacy of various monitor and diagnostic test technologies applied to polymer bushings

Approach

Guidelines on specification and maintenance of polymer bushings: Work will continue to refine and share the summation of learnings observed through the different research projects in P37.113. Additionally, findings through the shared operating experience of participating utilities into a series of guidelines on application, installation, operation, maintenance, and diagnostics of polymer bushings are proposed to be collected and summarized.

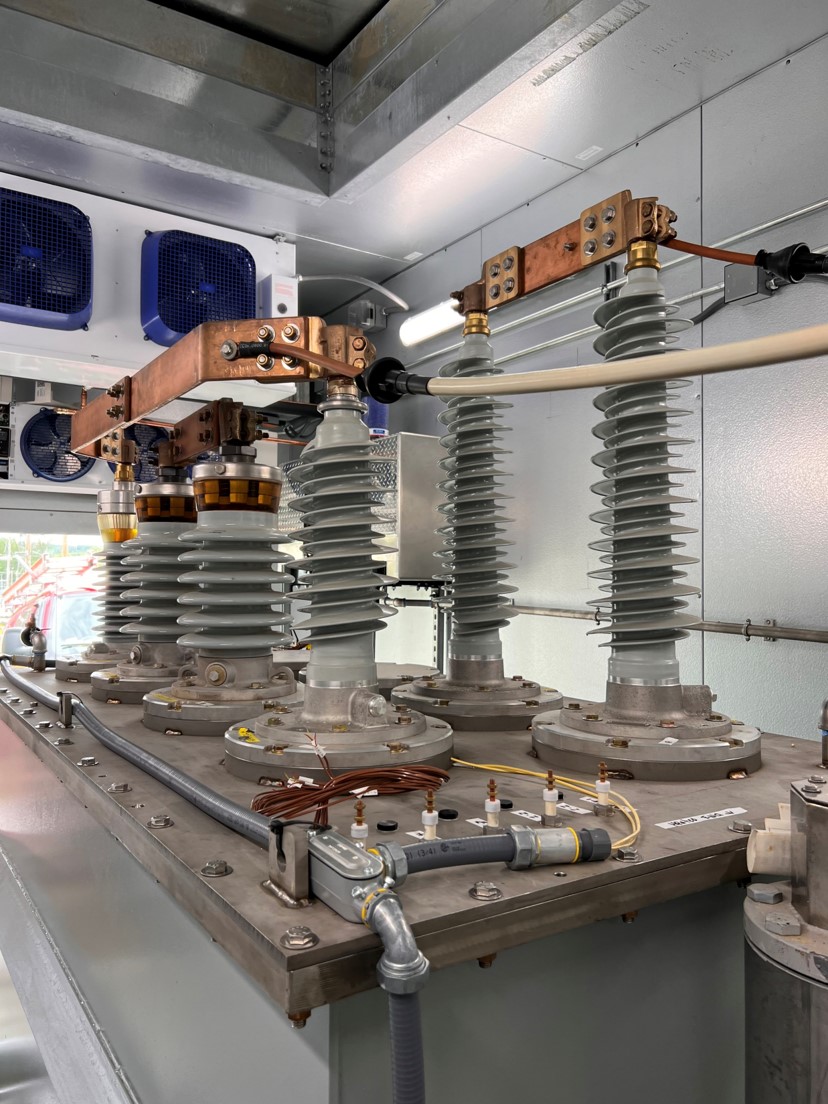

Performance of polymer bushings under extreme environmental conditions and operating stresses: Long-term exposure and testing of dry-type bushings is planned to be continued at full scale in an outdoor setting. The EPRI 138-kV research substation in Lenox, Massachusetts, affords the opportunity for an ideal location for outdoor testing under a wide range of ambient temperatures and precipitation types. Rain spray equipment is available to simulate a wet climate when desired. The bushings can be simultaneously energized to rated voltage while circulating currents up to, and in excess of, rated current. This test program began in 2019 and has been ongoing.

Targeted testing of specific concerns: While full-scale exposure and testing in the EPRI 138-kV research substation is highly valuable, it requires significant time. To expedite learning and provide actionable insights on specific concerns, like sensitivity to overloading or high mechanical stresses, EPRI intends to conduct targeted tests addressing issues identified by participating members. Topics of interest to explore include sensitivity to overload (load and temperature), and tests on bushing reliability under high cantilever forces, which could occur during through-fault conditions.

Analysis of the reliability and performance experience of polymer bushings: This task aims to provide the results of a broader study to classify the reliability, performance, and life expectancy of polymer bushings utilizing voluntary contributions of data and field experience from interested members.